Super Sale EU/UK/US Ship V2.2.2 Xhorse Dolphin XP-005 XP005 Key Cutting Machine with M5 Clamp Support Sided/Track/Tibbe Keys

EU Ship, NO Tax!

All 4% OFF, except bottom price items.

Better price, please contact Susie!

Skype: xhorsevvdi.com

Whatsapp:+86-13983756354

Related Download Files

Product Description

- Xhorse Dolphin XP-005 Key Cutting Machine is with a rich database, multi-purpose clamps, and built-in lithium battery.

- Dolphin XP005 is used on App via Bluetooth for both IOS and Android.

- More Than 60 Global Brand, 2000 Car Models and 20000 All Key Lost Database

Xhorse Dolphin XP-005 Key Cutting Machine

Dolphin XP-005 Bullet Points:

- With built-in battery inside. Support to take out to use.

- M5 Clamo, fully replace M1, M2 Clamp.

- Full capabilities of Condor XC-Mini.

- Newest Firmware version: V2.2.2 Lifetime free update online via Xhorse APP. Database ver. V129. If KM12, Newest Firmware 2.2.2. If not KM12, newest is 1.7.8.

- 1 Year Warranty for the Machine and 6 Months Warranty for Battery.

- Xhorse APP Language: English, German, Spanish, Persian, French, Hebrew, Hindi, Indonesian, Italian, Korean, Polish, Portuguese, Russian, Thai, Turkish, Ukrainian, Vietnamese (free to switch now)

- Support Cut Sided, Track, and Tibbe Keys, Household Keys (with optional M4 Clamp)

- Newly support plastic key and aluminum key.

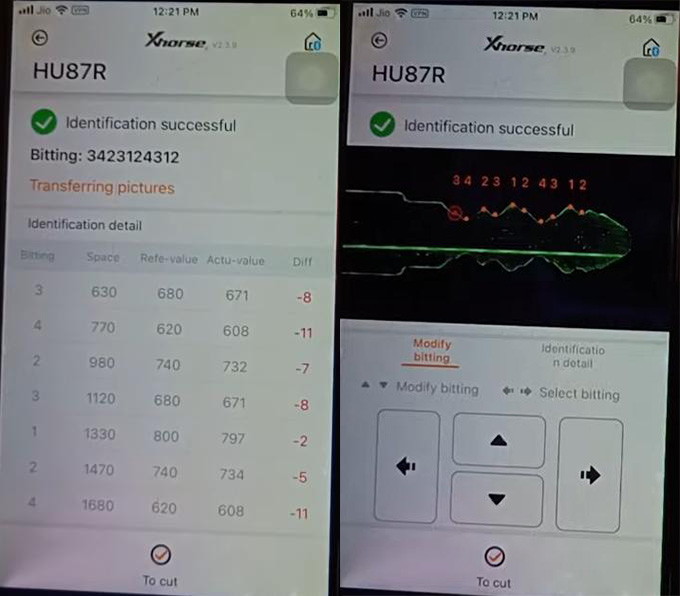

6. Optical Key Bitting Recognition (Work with KEY READER) Xhorse Dolphin cutting machine release read bitting from key blade photo, support get bittings from photo.

7. Works on smart mobile phone application via bluetooth connection.

8. Free Download Xhorse Dolphin XP-005 User Manual

Top 16 Reasons for XP-005 key duplicator:

- XP005 has all the capabilities of Condor XC Mini.

- Key Duplication

- All Key Lost

- Massive vehicle data

- Cut by Bitting

- Find bitting

- Support self-calibration

- Optical recognition bitting

- Support universal key decode for multiple key types

- Take photos to recognize bitting

- Customize key data

- Built-in lithium battery

- Smart APP control

- Multi-purpose clamps

- Lifelong free upgrade service & technical support

- Support Sided/Track/Tibbe keys

Dolphin XP-005 Clamps:

1. M5 Clamp

2. Optional M3, M4 Clamp (You need buy separately)

V128 Database New Update:

Add BMW F900R data

Fix Toyota Sienna data

Fix others

Dolphin Key Cutting Machine Features:

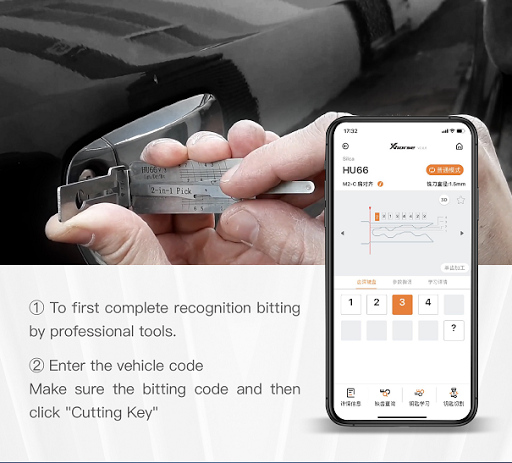

1. With a smart App, fast and Effective Solutions are provided to make you an expert in all key lost fields.

To first complete recognition bitting by professional tools. Enter the vehicle code. Make sure the bitting code and then click "Cutting Key"

SMART APP CONTROL

Support multi-language · Easy to Use · Time-Saving · Upgrade for free

DOLPHIN XP-005 can be easily controlled by Xhorse APP on your phone, tablet PC, and other intelligent terminals to complete Cut by Bitting, Key Duplication, All Key Lost, Find Bitting, Key data Customization, Optical recognition bitting, Take photos to recognize bitting, etc.

2. Rich Database

Our built-in powerful database covers over 100 car brands, 2,000 car models, and 20,000 key data. We provide a lifelong database upgrade service for free!

3. Built-in Lithium Battery

Select well-known lithium battery, stable and reliable, support cutting work without no power supply access.

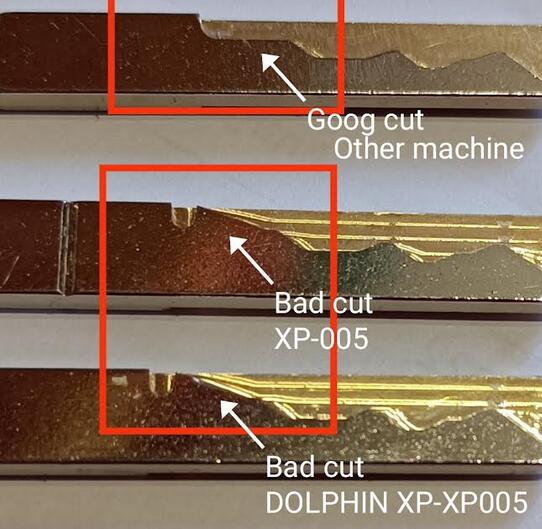

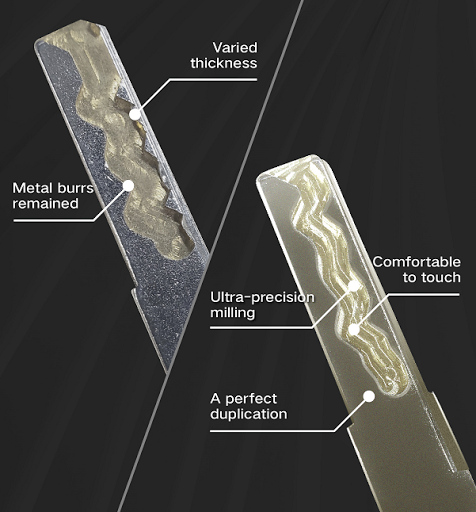

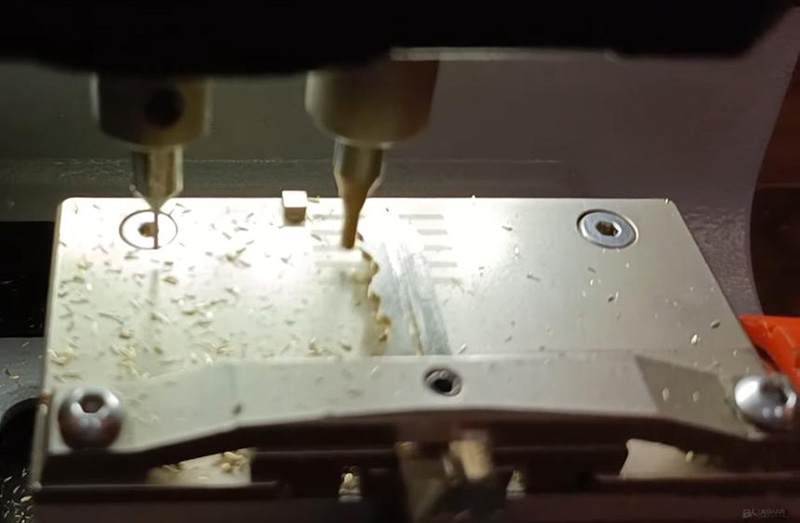

4. High Precision Cutting Results

Key cutting results competition

Keys cut by some machines VS Keys cut by DOLPHIN XP-005

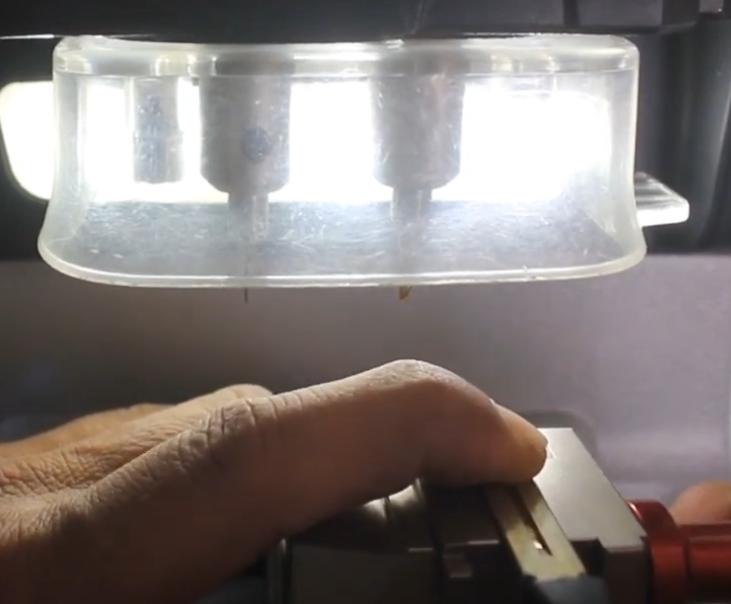

5. LED light and Non-Slip lifting handle

The status indicator LED light is ideal for checking key cutting status clearly, and also ensuring the regular works in the dark.

Ergonomic design, comfortable and effortless.

Used to secure the machine in a fixed position and moving it with better control and pulling power.

The excellent key duplicator maintains stable performance even in extreme weather.

6. Multi-Purpose Clamps

Standard Clamps: M1 Clamp and M2 Clamp

M1 Clamp supports key types: standard single sided, standard double sided.

M2 Clamp supports key types: 2 track external, 4 track external, Dimple, Channel track, 4 track internal;

Optional Clamps: M3 and M4 Clamp

M3 Clamp supports key types: Ford F201 and Citroen SX9

M4 Clamp supports key types: Residential key types

7.Timely and Portable solutions

Compact design, its net weight, only 13kg, much easier to provide users outdoor and roadside services.

Xhorse Dolphin XP005 vs Condor XC-Mini Plus vs Dolphin XP005L Comparison:

Xhorse Dolphin Key Cutting Machine is an entry-level product of the Condor CNC machine family. The body design is simple, it is very suitable for mobile use in the mobile scene, without operating screen, you need to connect a mobile phone or tablet, and install a dedicated app.

| Item | Xhorse Dolphin XP005 | Condor XC-MINI Plus | Dolphin XP005L |

| Image |  |

|

|

| Screen | Small Screen Only Display Battery, Bluetooth Status. | 7-inch Adjustable Touch Screen | 5-inch Adjustable Touch Screen |

| Manipulation | Phone APP | Touch Screen/Phone APP | Touch Screen/Phone APP |

| Clamp | Standard Clamps (M1, M2) Optional Clamps (M3, M4) |

Standard Clamps (M1, M2) Optional Clamps (M3, M4) |

Standard Clamp (M5) Optional Clamps (M1, M2, M3, M4) |

| Protection Mask | Simple | Comprehensive | Comprehensive |

| Offline operation | Not Support | Support | Support |

| Built-in Database | No | Yes | No |

| Built-in Battery | Built-in Lithium Battery | No, Need Optional Accessory: Power Supply Adapter with Built-in Battery | Built-in Lithium Battery |

| Update | Software (Database): Xhorse APP Firmware: Upgrade Kit on PC |

Software (Database): Xhorse APP Firmware: Upgrade Kit on PC |

On Machine via Wi-Fi |

| VVDI MB/Key Tool Plus Binding Profit |

1 Free MB Token Everyday after Binding | 1 Free MB Token Everyday after Binding | 1 Free MB Token Everyday after Binding |

| Gross Weight | 18Kg | 22.9Kg | 18.5Kg |

| Net Weight | 15Kg | 18Kg | 13Kg |

| Warranty | 1 year | 3 years | 1 year |

Dolphin XP005 Parameters

| Working Temperature | -10~50℃ |

| Input Voltage | 12-24V |

| Battery Capacity | 64.75wh |

| Cutting Power | 100W |

| Standby Power | 15W |

| Motor Rotation Speed | 10000-13000RPM |

| Rated Torque | 0.15 Nm |

| USB Port | USB2.0 |

| Machine Dimension | 315*218*270mm |

| Package Dimension | 510*315*345mm |

| Net Weight | 15kg |

| Gross Weight | 18kg |

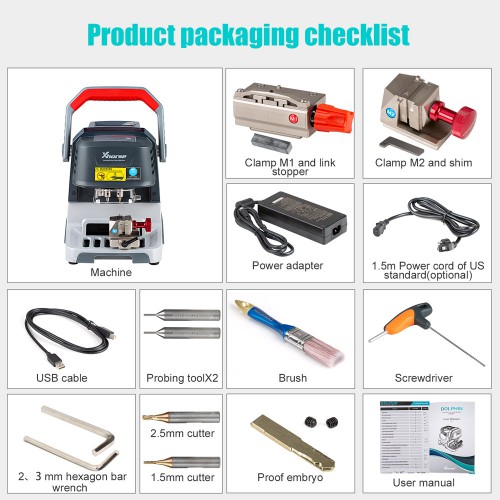

Xhorse Dolphin XP005 Package List:

1pc x 3mm hexagon bar wrench

Optional Cutters and Probes You May Need:

Dolphin XP-005 Support List (2020-01-21):

| BRAND | CARS | Key Profile Code | Key Code Series | Xhorse ID | Cuts |

| MARUTI | Maruti Swift, Dzire etc. | HU133R/HU87R | IP5001-IP6308 | 1098 | 10 |

| MARUTI | Swift, Dzire, New Wagonr | Swift-New | only duplication | 16360 | 10 |

| MARUTI | Suzuki Alto/WagonR/Eeco | Swift-New | 71001-72500 | 1270 | 8 |

| MARUTI | Suzuki Omni | SZ13RP | 6501-7704 | 30 | 7 |

| HYUNDAI | Hyundai Santro | HYN10 | R1-1000 | 8 | 8 |

| HYUNDAI | Hyundai Verna (old model) | HYN11/HYN15 | V1-V2500 | 1753 | 8 |

| HYUNDAI | Hyundai Accent /Elantra | HYN11/HYN15 | T1-1000 | 8 | 8 |

| HYUNDAI | Hyundai New i20/Xcent | HYN14 | M1-2500 | 1507 | 8 |

| HYUNDAI | Hyundai i20 Elite | HYN14 | P1-2500 | 1507 | 8 |

| HYUNDAI | Hyundai i20 (old) | HY22 | P1-2501 | 1360 | 6*6 |

| HYUNDAI | Hyundai i10/Eon | HYN14 | P1-2502 | 1507 | 8 |

| HYUNDAI | Hyundai Verna Fluidic (2010-2017) | VERNA | 85001-87079 | 16005 | 8 |

| HONDA | Honda City, Civic, Accord, Jazz | HON66 | K001-N718 | 2086 | 6*6 |

| HONDA | Honda Amaze/Brio | BRIO | 25001-28081 | 16111 | 6*6 |

| TOYOTA | Toyota (all models) | TOY43 | 50000-69999 | 940 | 10 |

| TOYOTA | Toyota Crysta | TOY48 | 40000-59999 | 1124 | 5*5 |

| MAHINDRA | Bolero Minda | Bolero (Min.) | 5000-6251 | 16121 | 6 |

| MAHINDRA | Mahindra Xylo/Scorpio/Quanto | HU101 | 00001-03001 | 16001 | 10 |

| MAHINDRA | Mahindra XUV-500 | XUV500 | 85101-86800 | 16003 | 8 |

| SKODA | Skoda/VW/Audi | HU66 | 947 | 8 | |

| NISSAN | Nissan Micra/Sunny | NSN14 | 00001-22185 | 242 | 10 |

| RENAULT | Renault Scala/Pulse | NSN14 | 00001-22186 | 242 | 10 |

| RENAULT | Renault Logan/Duster | VAC102 | 0001-4092 | 1034 | 6 |

| FORD | Ford Figo/Fiesta (tibbe) | FO21 | T1-T1050 | 278 | 6*6 |

| FORD | Ford Endeavor | MAZ24R | 10100-12283 | 47 | 10 |

| FORD | Ford Ecosport | HU101 | 0001-4000 | 1220 | 10 |

| FIAT | Fiat Palio | GT15R | W1-9640 | 253 | 9 |

| FIAT | Fiat Punto/Linea | SIP22 | DE1-DE11210 | 1190 | 8 |

| CHEVROLET | Chevrolet Beat/Sail | HU43 | M1-1200 | 8 | |

| CHEVROLET | Chevrolet Cruze | HU100 | Z1-2000 | 1242 | 8 |

| CHEVROLET | Chevrolet Captiva | DW05 | V0001-3200 | 79 | 8 |

| PIAGGIO | Piaggio Vespa | GT15R | W1-9640 | 253 | 9 |

| BMW | BMW | HU92 | 0001-8100 | 1239 | 9 |

| BMW | BMW | HU58 | BH010001-241450 | 261 | 8 |

| MERCEDES | Mercedes Benz | HU39 | 700001-703000 | 1078 | 8*8 |

| MERCEDES | Mercedes Benz | HU64 | 0001-0355 | 1082 | 10 |

| MITSUBISHI | Mitsubishi (Right) | MIT11R | 30010-32009 | 3 | 8 |

| MITSUBISHI | Mitsubishi (Right) | MIT12R | 30010-32009 | 3 | 8 |

| MITSUBISHI | Mitsubishi (Left) | MIT8 | E5001-E7700 | 8 | |

| TATA | Tata Indica Vista/Manza | S0001-S2000 | 16094 | 10 | |

| HERO | Splendor/NXG/Karizma etc. | 1001-2040 | 16004 | 8 | |

| HERO | Splendor/NXG/Karizma etc. | 2001-3040 | 16004 | 8 | |

| HERO | Splendor Minda | 3001-3858 | 16113 | 7 | |

| HONDA | Honda Activa/Shine | 8100-9113 | 16000 | 8 | |

| HONDA | Activa 3G/4G | 16093 | 8 | ||

| HONDA | Activa 5G | 16357 | 8 | ||

| BAJAJ | Pulsar 220 / KTM | 00001-03001 | 16091 | 8 | |

| BAJAJ | Discover/Pulser 180 | 5001-6174 | 16002 | 8 | |

| BAJAJ | Avenger New (same as TVS WEgo) | 2001-3170 | 16109 | 7 | |

| SUZUKI | Access New | 1001-2252 | 16115 | 6 | |

| SUZUKI | Burgman Street (same as Access) | 1001-2252 | 16115 | 6 | |

| SUZUKI | Swish (same as Jupiter) | 5001-6174 | 16095 | 8 | |

| SUZUKI | Gixxer | 2001-3170 | 16109 | 7 | |

| YAMAHA | R15, Libero | 2001-3174 | 16112 | 8 | |

| YAMAHA | Ray | 2001-3174 | 16112 | 8 | |

| TVS | Jupiter (with Magnet) | 1001-2174 | 16109 | 7 | |

| TVS | Wego | 2001-3170 | 16109 | 7 | |

| MAHINDRA | Gusto | 2001-3170 | 16109 | 7 | |

| MAHINDRA | Duro | 3001-3858 | 16110 | 7 | |

| *the ones marked in RED will be added soon on Xhorse ID list. Key cutting is already supported. | |||||

Contact US:

If you have any questions, please do not hesitate to contact us.

Shipping Method and Delivery Time:

EU, US, UK ,RU Warehouse: 3-7 working days. We have stocked up hot sale items in US, UK ,RU, EU Warehouse, Fast Delivery No Tax. But if overseas warehouse is sold out, we will send from Hongkong by DHL.

EU warehouse only for EU customers. UK warehouse for UK address only! US the same, and not includes overseas territories. No customs tax.

DHL: 3-7 working days. And EU address by DHL invoice value can't be less than 150USD. If your address is remote area for DHL, need to pay remote cost about 35USD or no extra fee ship by YANWEN.

Yanwen Express: 5-17 working days. No customs Tax or remote cost for EU Countries.

About VAT, if company buyer needs the VAT invoice, please pay the VAT, then we provide VAT invoic for you to do tax refund.

Videos

Xhorse Condor Dolphin Key Cutting Machine Demo Video

How to use Xhorse Dolphin XP005 Cut HU101 Key and Calibration?

How to do space and depth fine-tuning via Xhorse App on DOLPHIN XP-005?

Tech Support

1.Free Download (Xhorse App, Upgrade Kit, Firmware Update Drivers)2.Error & Fix

3.Guide

1.Free Download

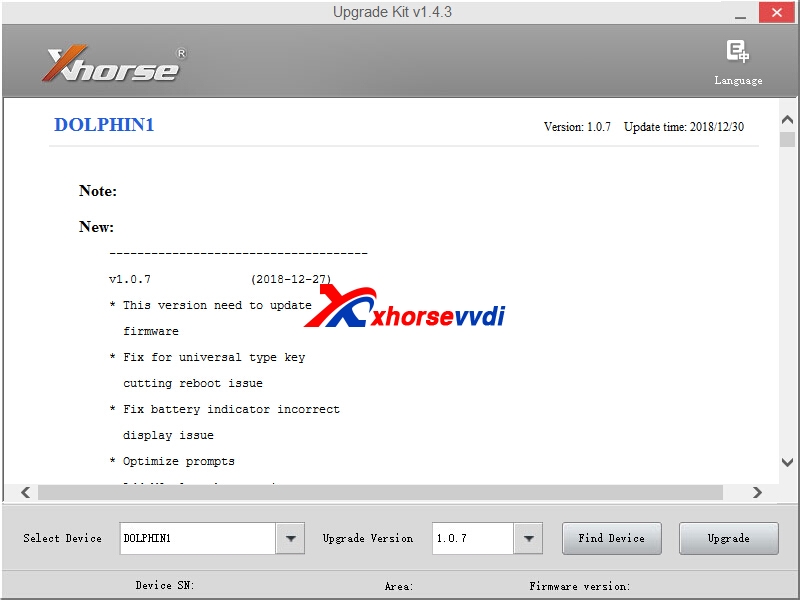

Dolphin XP-005 key cutting machine, use xhorse app on phone, you can update database in xhorse app. Condor Dolphin update firmware via xhorse update kit software.

1.Xhorse App

Database udpate

Firmware Update

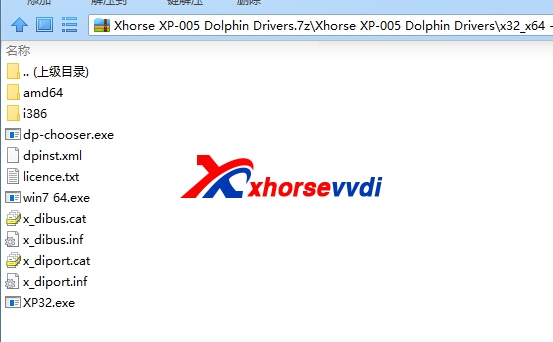

3.Frimware Update Drivers

Firmware Update Drivers Download

2.Error & Fix

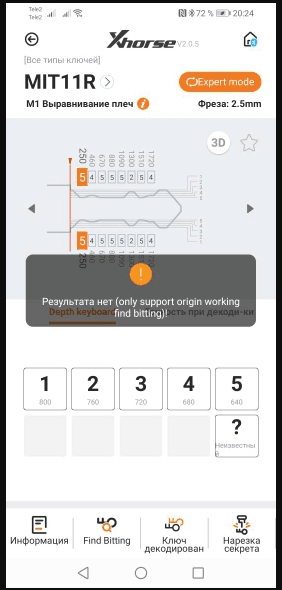

1)"Only support origin working find bitting"

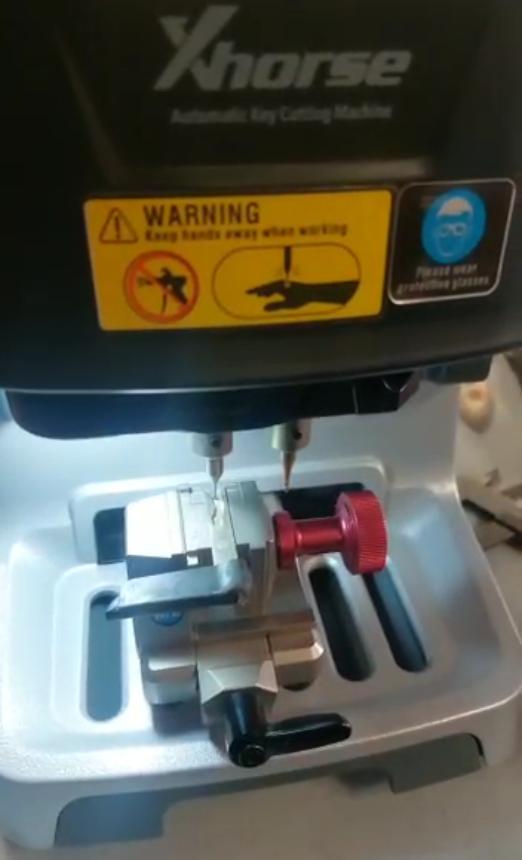

2)Machine can't fix clamp

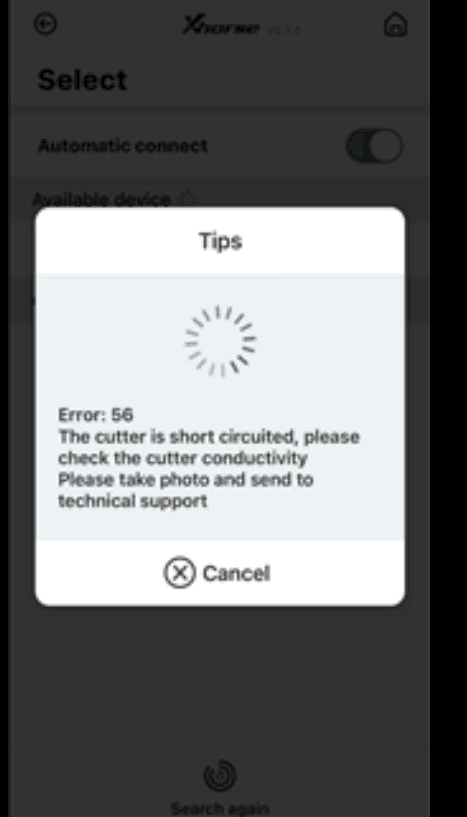

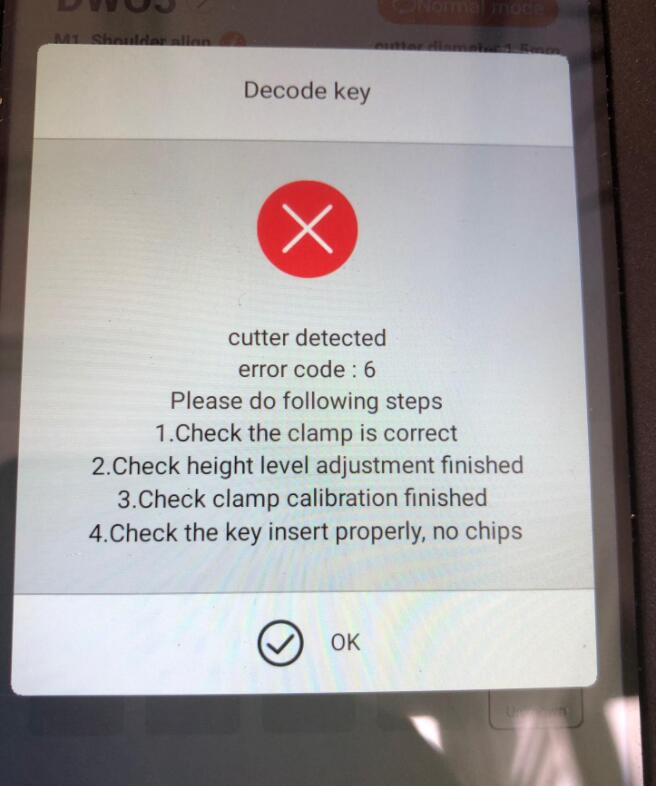

3)"Error: 56" "error code: 6"

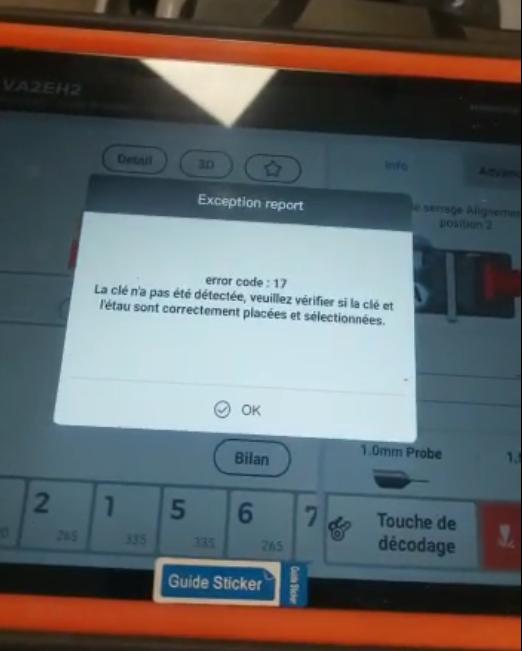

4)"error code: 17 No key is detected, please check whether a key is correctly positioned and selected"

5)Cutter wont touch key blade

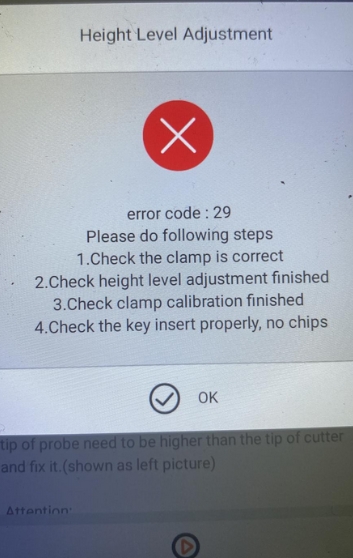

6)"error code: 29"

7)Noise and rough cutting

8)New keys of different types cut are incorrect

1)"Only support origin working find bitting"

Solution: If the key is missing bitting, only those original numbers can be found (automatically filled)

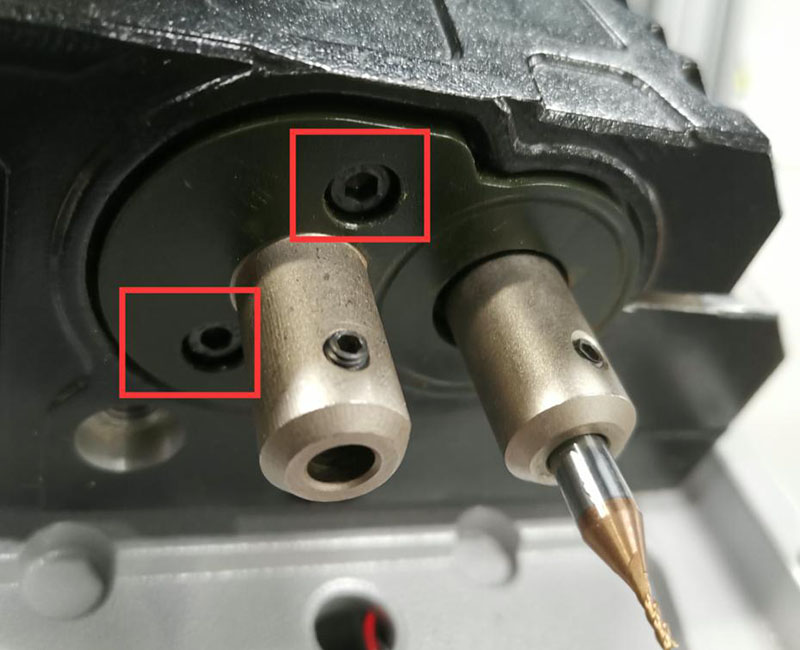

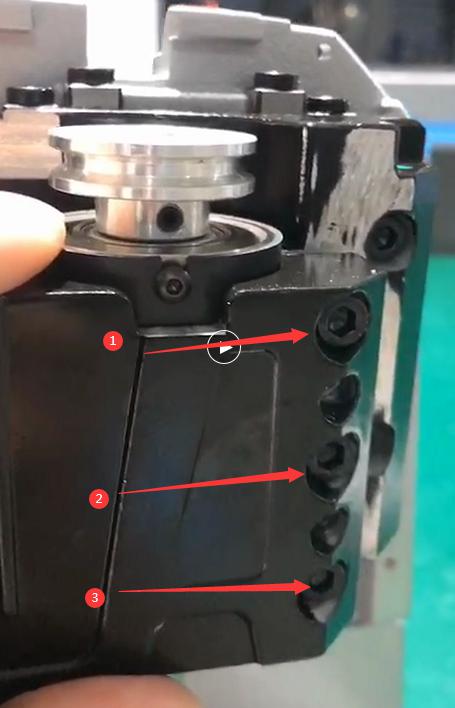

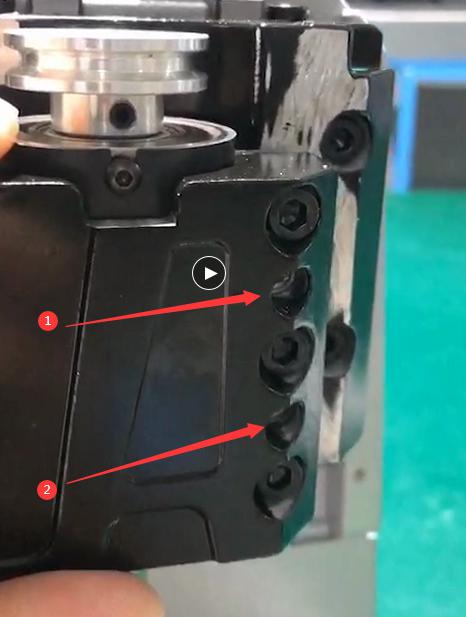

2)Machine can't fix clamp

Reason: The fixer lacks the part circled.

Solution:

The fix consists of two part as below:

Check original package, and there should be one; If not, buy a new one.

Combine them, and the fixer should fix clamp normally.

3)"Error: 56" "error code: 6"

Solution:

Check the steps as the prompts. (height level adjustment, clamp calibration etc.)

Do the Electrical Conductivity Measurement.

If the cutter and the probe don't conduct, disassemble the machine and test abnormal conductivity of the cutter/probe.

4)"error code: 17 No key is detected, please check whether a key is correctly positioned and selected"

Solution: Put shim below to raise the original key so the machine could learn it

5)Cutter wont touch key blade

Reason

The problem is a dysfunctional battery.

The machine disconnects and the probe & the cutter restore because it is powered down and reboot automatically.

Solution

Buy a new battery and replace the broken one.

6)"error code: 29"

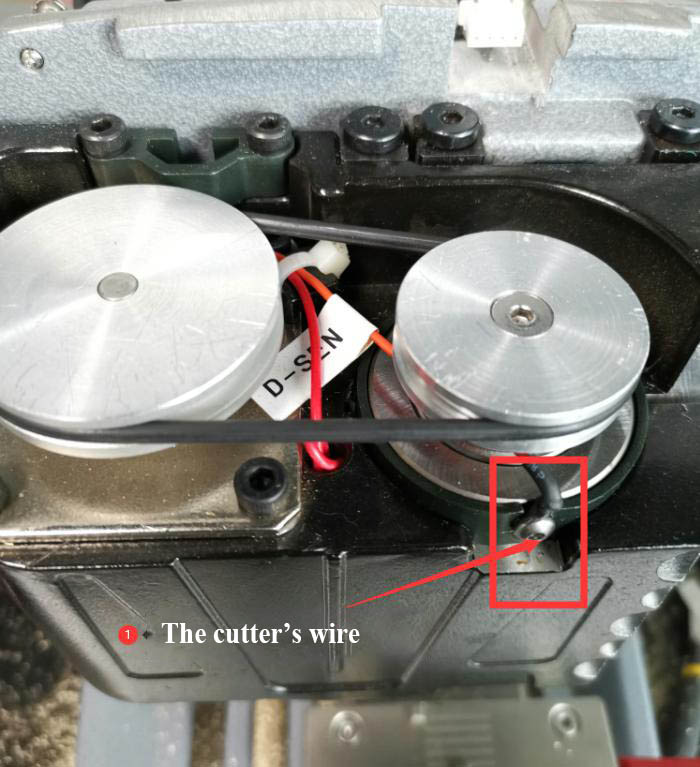

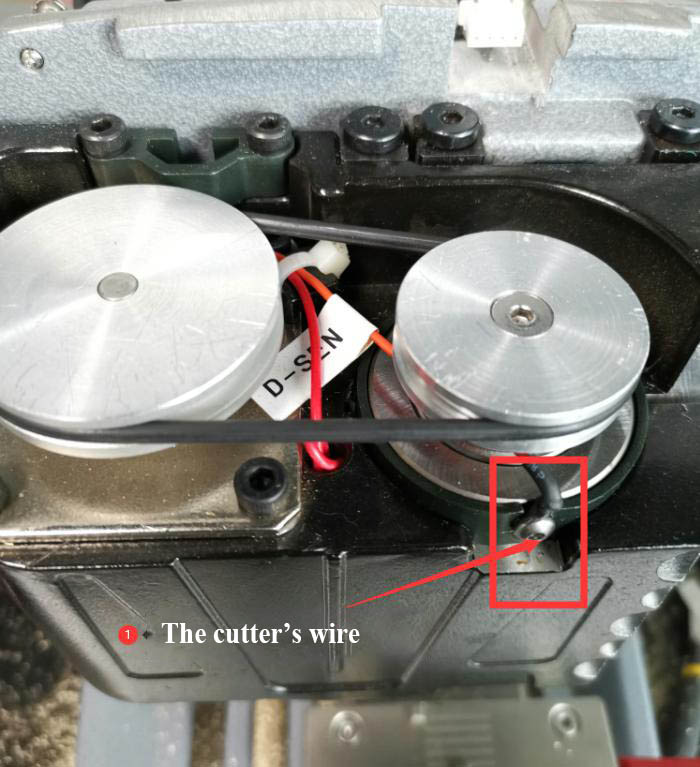

Reason: probe/ cutter is short-circuited due to metal filings

Solution:

Test if probe/ cutter is short-circuited via Electrical Conductivity Measurement (cutter is short-circuited in this case)

Open Machine and remove metal filings around the wire of cutter.

7)Noise and rough cutting

Solution:

Step 1

Remove back cover of the machine.

Care the cables inside.

Step 2

Clean iron filings inside by a soft brush instead of a air gun.

Particularly clean filings on here.

Step 3

Lube ball screw and guide rail of the motor.

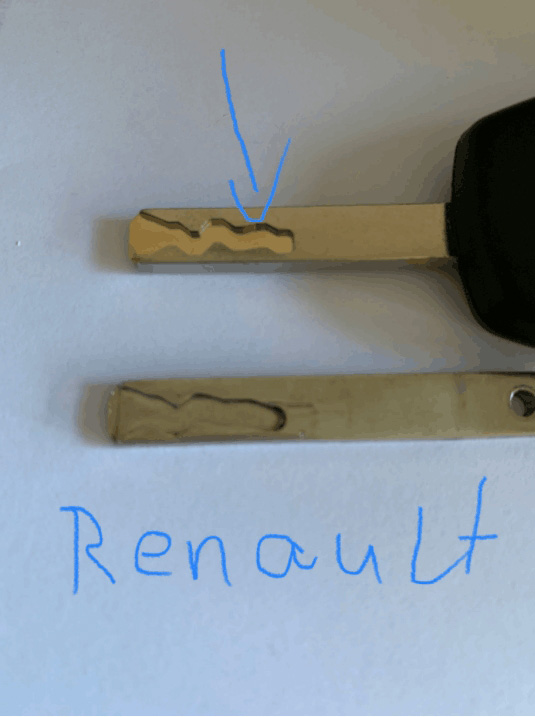

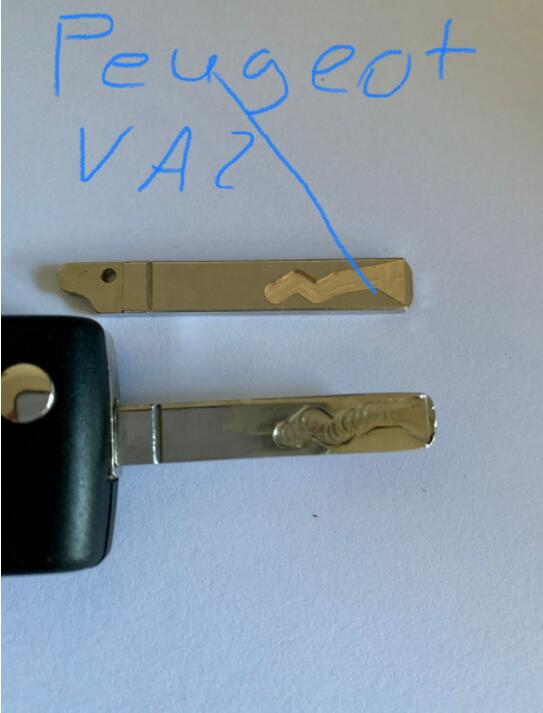

8)New keys of different types cut are incorrect

(in this case Renault, Peugeot VA2, HU100 Opel)

Possible reason:

The sensors or the cables inside don’t function well.

Solution:

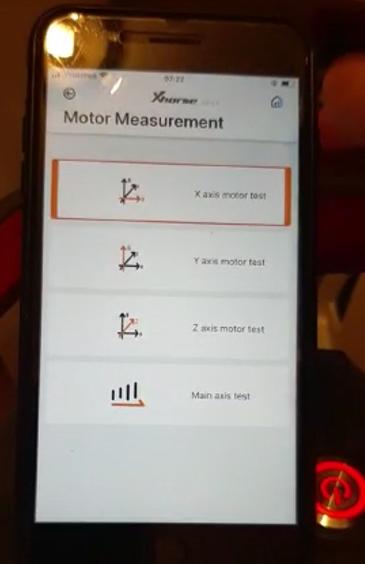

Motor Measurement, machine is likely to be sent back to factory for repair (in this case X-axis is broken)

3.Guide

1)Xhorse APP Learn key via Photo

2)Electrical Conductivity Measurement

3)Test conductivity of cutter/probe

4)Work with Key Reader

5)Cut TOY40 Key by Code

6)Cut Used/Unfinished or Plastic/Aluminum Key

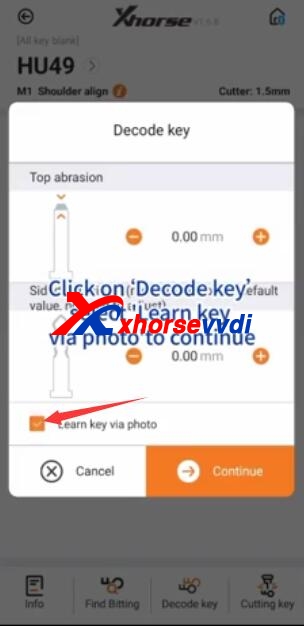

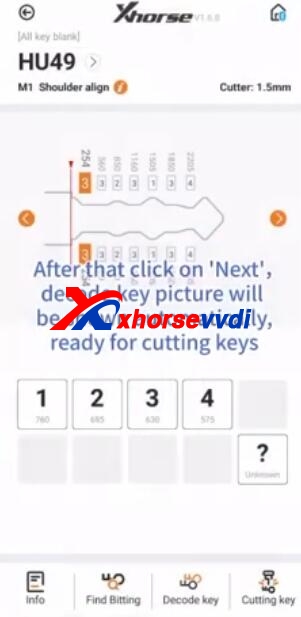

1)Xhorse APP Learn key via Photo

Xhorse APP Dolphin XP-005 can support read key bitting from key blade photo.

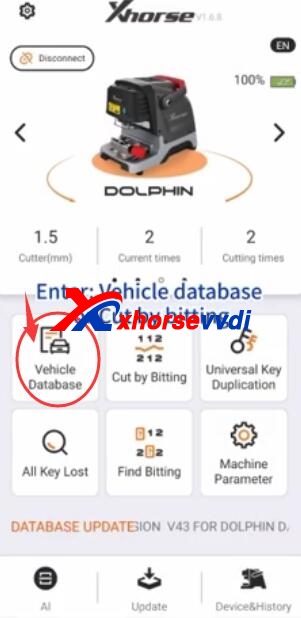

1.Choose vehicle database in xhorse app, Dolphin xp-005.

2.Choose the car brand.

3.Jetta,then HU49.

4.Tick on “Learn key via Photo”

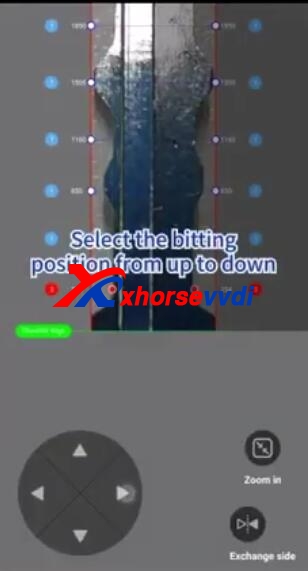

5.Please put the key blade horizonal in the fixed area,keep key on the top.

6.Rotate and zoom in the photo,adjust photo to the align line.

7.Dcode OK,then continue to cut key.

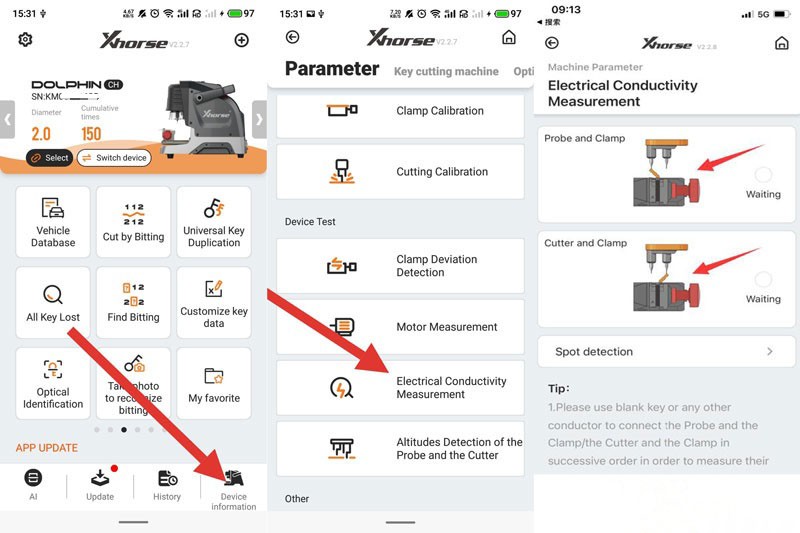

2)Electrical Conductivity Measurement

Go to Xhorse app.

Device information>>Electrical Conductivity Measurement

1)Probe and clamp

2)Cutter and clamp

Use a blank key or a conductor to short-circuit the clamp and the probe/cutter as the prompt.

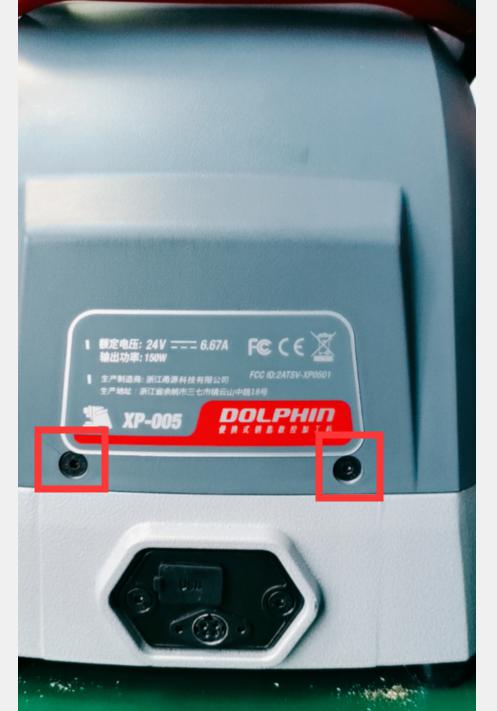

3)Test conductivity of cutter/probe

Step 1

Unscrew the back of Dolphin XP-005, and watch the cables inside.

Step 2

Remove the back.

Unscrew the cable and the two Phillips screws.

Turn to the front side.

Unscrew the little rubber cover, and at behind are screws.

Then unscrew the long metal by a hexagon bar wrench.

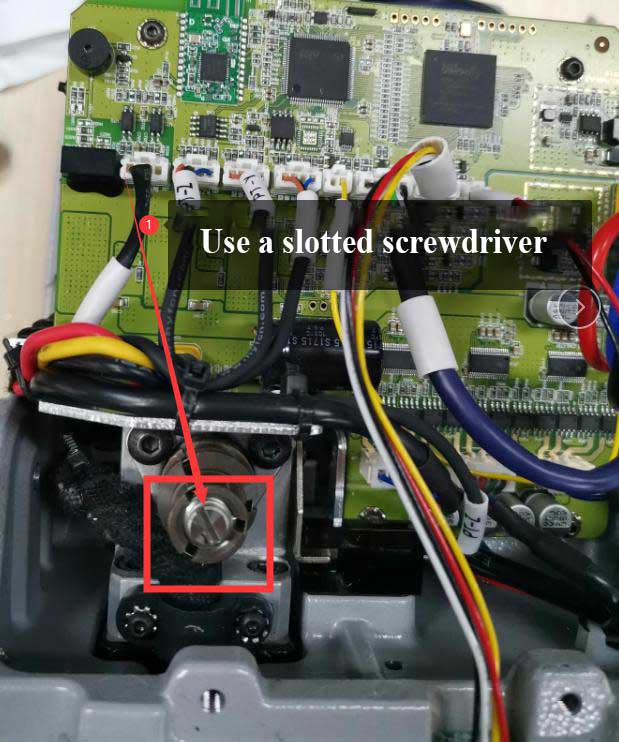

Step 3

Use a slotted screwdriver to turn the screw so that the Z-axis and the outer cover are in the same horizontal plane.

Take down the outer cover of the Z-axis after the adjustment.

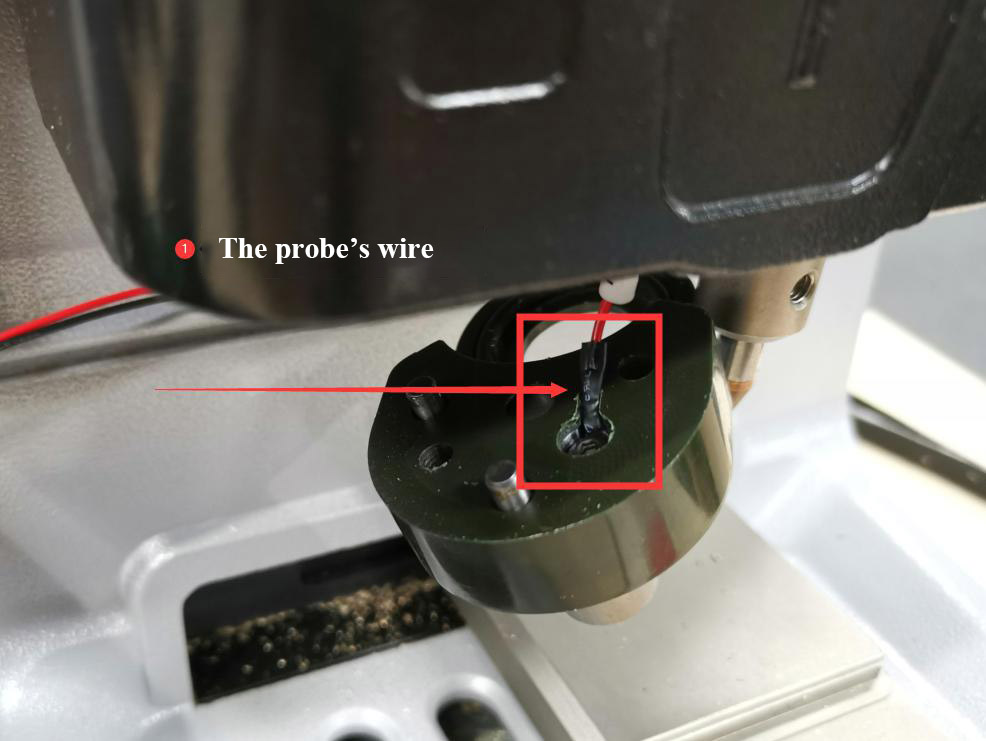

Unscrew the screws beside the probe.

Care the wire inside when removing the base.

Step 4

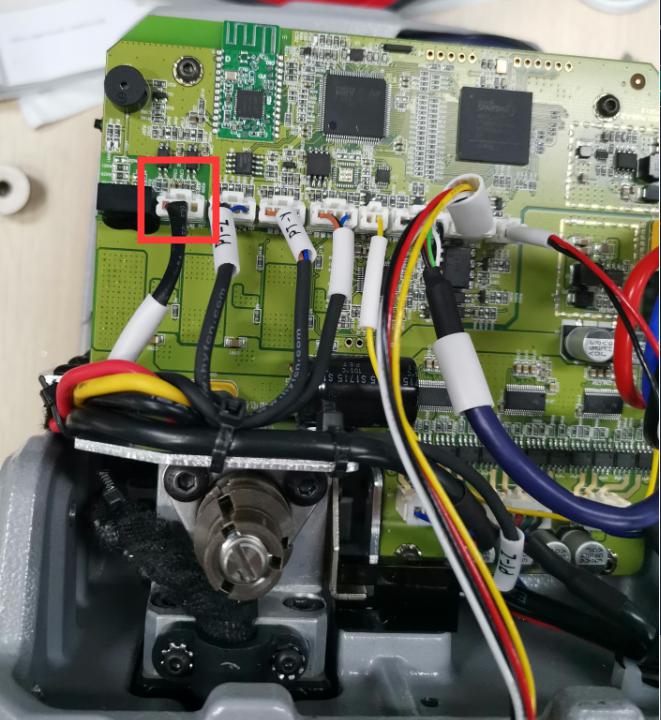

When the above steps are complete, now we can test whether the cutter’s wire and the probe’s wire are circuited or short-circuited.

The wires should be tested together with wires in the power board.

Unplug and plug the wire in the power board again before we test if the conductivity is normal.

Step 5

This step is to test the cutter’s conductivity.

Unscrew the three screws on the Z-axis,

and fasten the two screws until we get a gap to take down the Z-axis.

Press the cutter’s hole and push the axis up.

Check if the white paper is broken.

If so, replace it.

If not, check if there are some iron filings inside the axis hole.

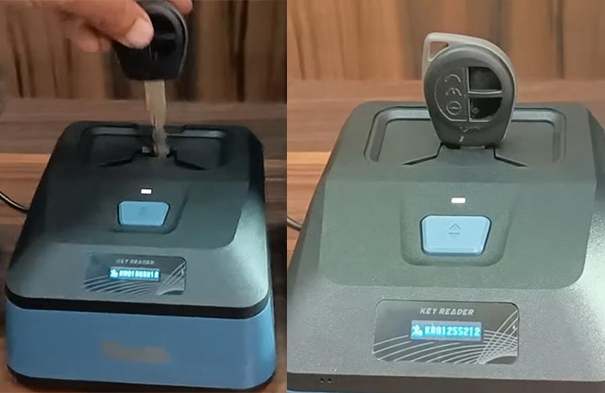

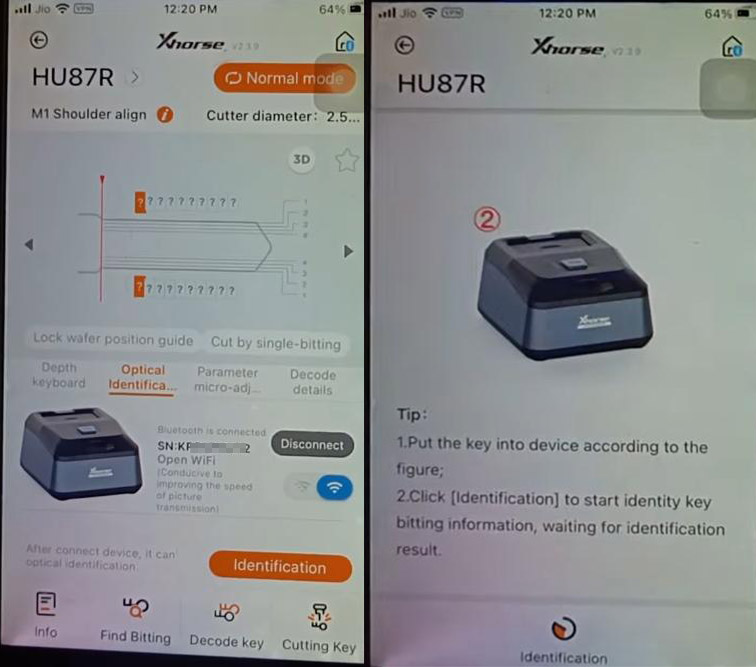

4)Work with Key Reader

Step 1. Decode

Path (Xhorse app):

Vehicle database>>Suzuki>>Swift>>new(after 2019)>>HU87R>>Optical identification>>Identification

Step 2. Cut

Put a new key blank on clamp M1 as required and click on “Cutting Key”.

Comparison

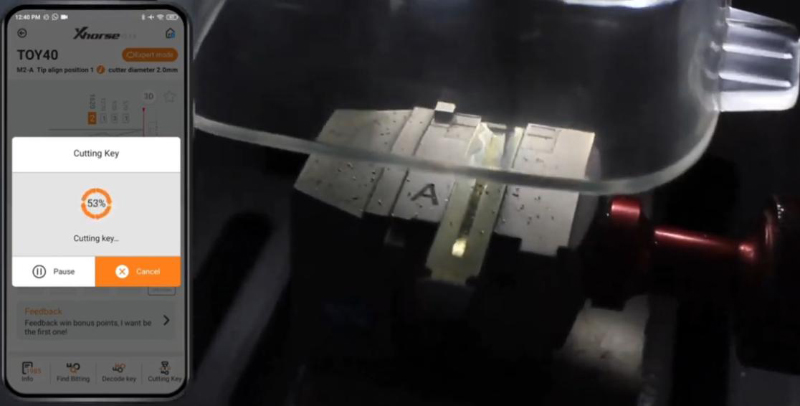

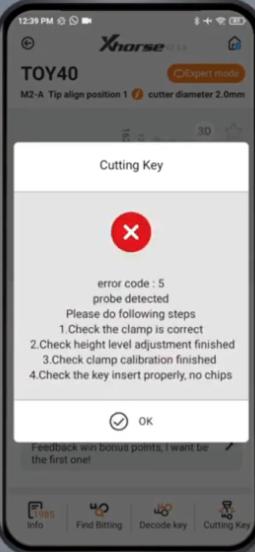

5)Cut TOY40 Key by Code

On Xhorse app, go to

All Key Lost>>Toyota

Input key code “88999”.

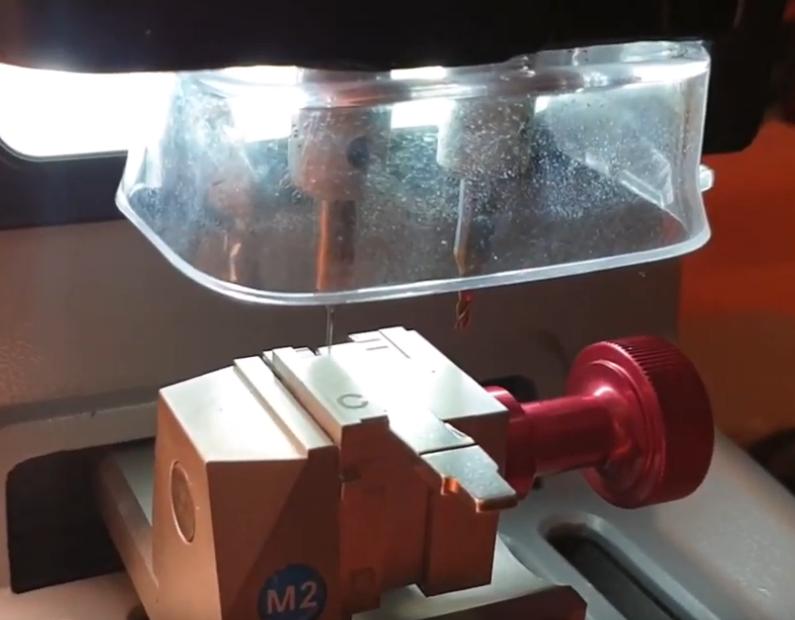

Prepare paper shims. (XP005 probe can’t detect such keys with only one side, so we need raise key blank by shims)

Put shims in clamp first.

Then put key blank.

Click “Cutting Key”.

If app prompts “error code: 5”, then we have to make key blank higher.

Complete!

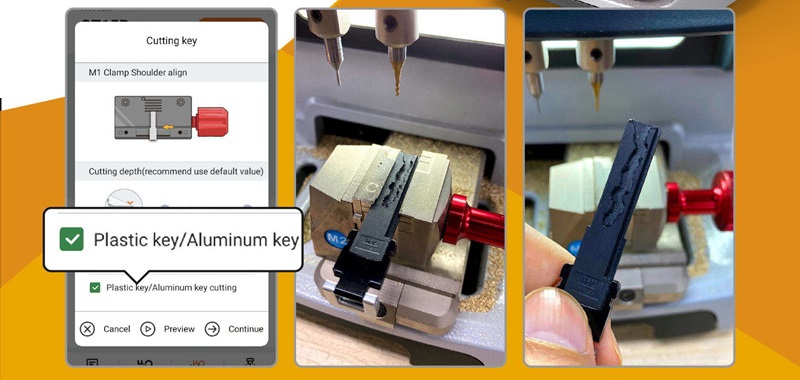

6)Cut Used/Unfinished or Plastic/Aluminum Key

Step 1

Put a new blank of the same type for the probe to detect.

Step 2

Once the identification is complete, click “Pause”.

Step 3

Remove the new blank, put the semi-cut key back in, and click “Continue”.

Step 4

Repeat process for the other side if needed.