How to use Condor Dolphin Key Cutting Machine XP-005

Matched product:

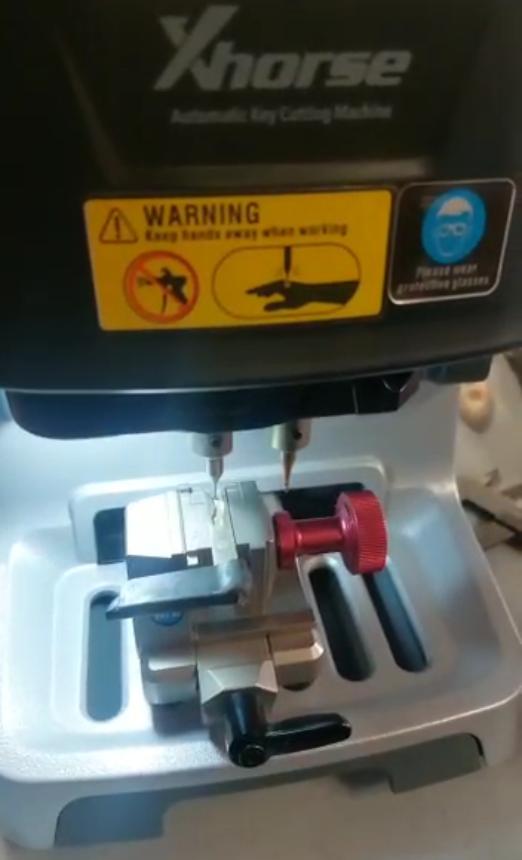

EU/UK/US Ship V2.1.7 Xhorse Dolphin XP-005 XP005 Key Cutting Machine XP0501EN Support Sided/Track/Tibbe Keys

- Item No. SL437

- Free Shipping

Dolphin XP005 is used on App via Bluetooth for both IOS and Android.

More Than 60 Global Brand, 2000 Car Models and 20000 All Key Lost Database

2.Error & Fix

3.Guide

1.Free Download

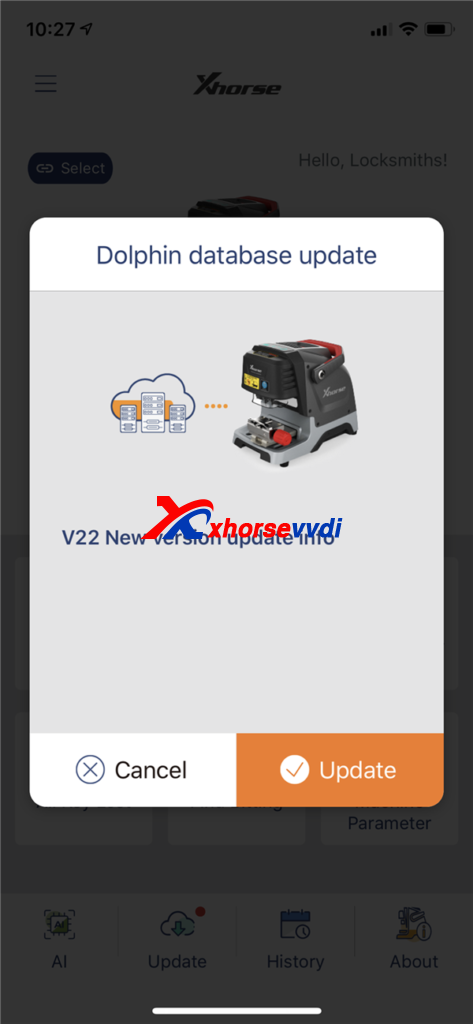

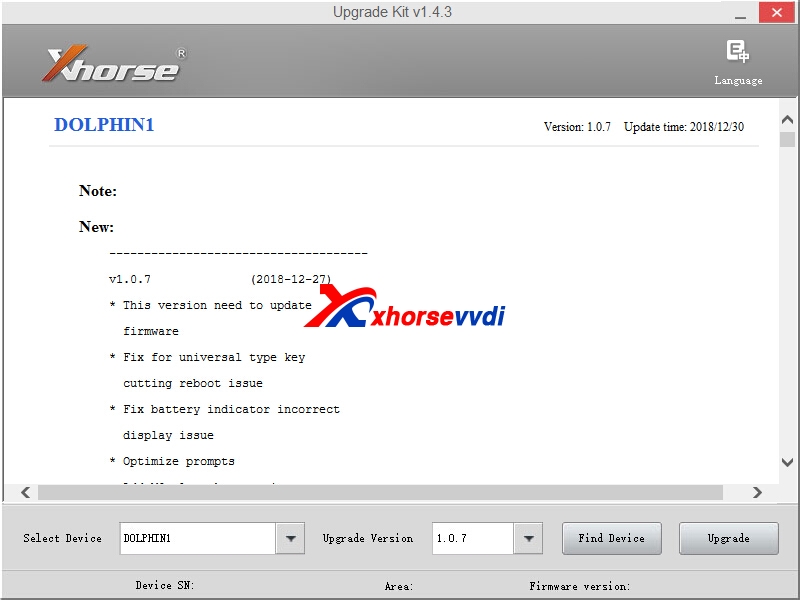

Dolphin XP-005 key cutting machine, use xhorse app on phone, you can update database in xhorse app. Condor Dolphin update firmware via xhorse update kit software.

1.Xhorse App

Database udpate

Firmware Update

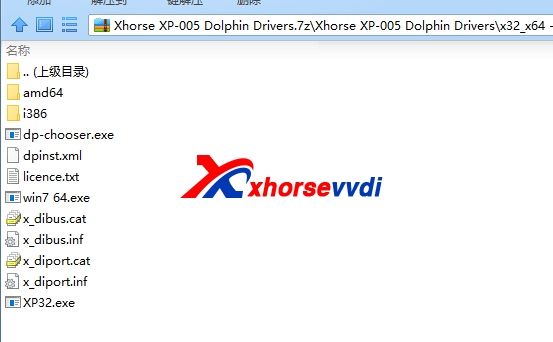

3.Frimware Update Drivers

Firmware Update Drivers Download

2.Error & Fix

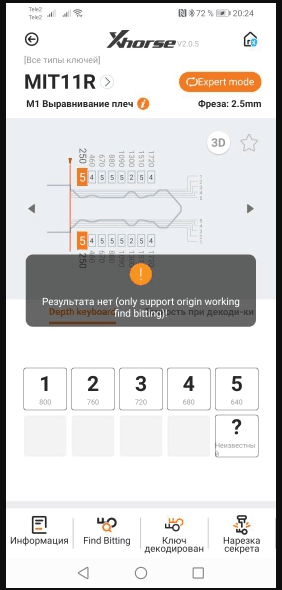

1)"Only support origin working find bitting"

2)Machine can't fix clamp

3)"Error: 56" "error code: 6"

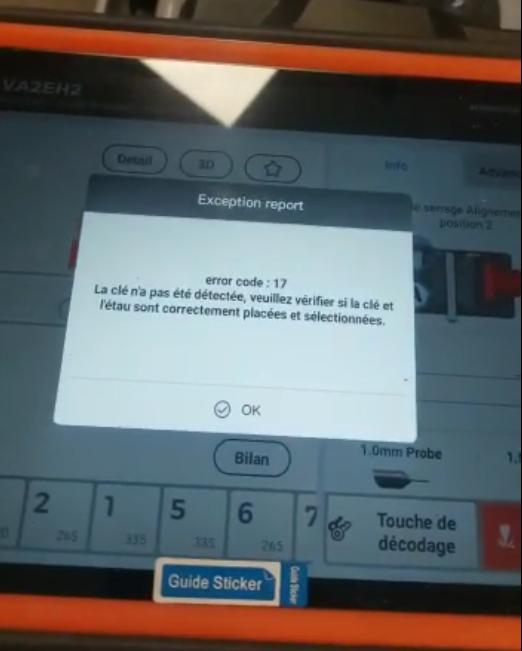

4)"error code: 17 No key is detected, please check whether a key is correctly positioned and selected"

5)Cutter wont touch key blade

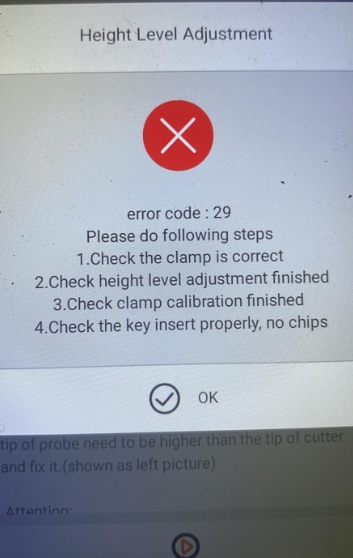

6)"error code: 29"

7)Noise and rough cutting

8)New keys of different types cut are incorrect

1)"Only support origin working find bitting"

Solution: If the key is missing bitting, only those original numbers can be found (automatically filled)

2)Machine can't fix clamp

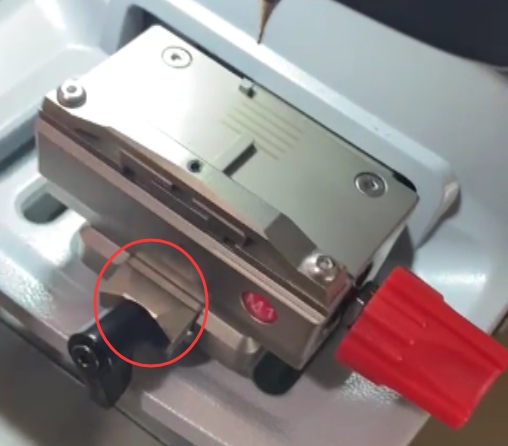

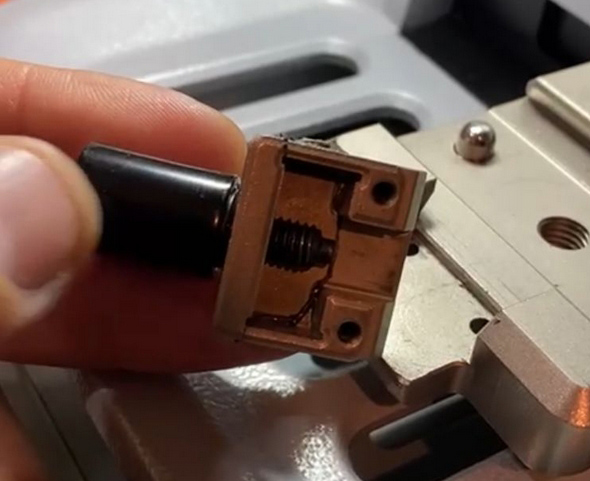

Reason: The fixer lacks the part circled.

Solution:

The fix consists of two part as below:

Check original package, and there should be one; If not, buy a new one.

Combine them, and the fixer should fix clamp normally.

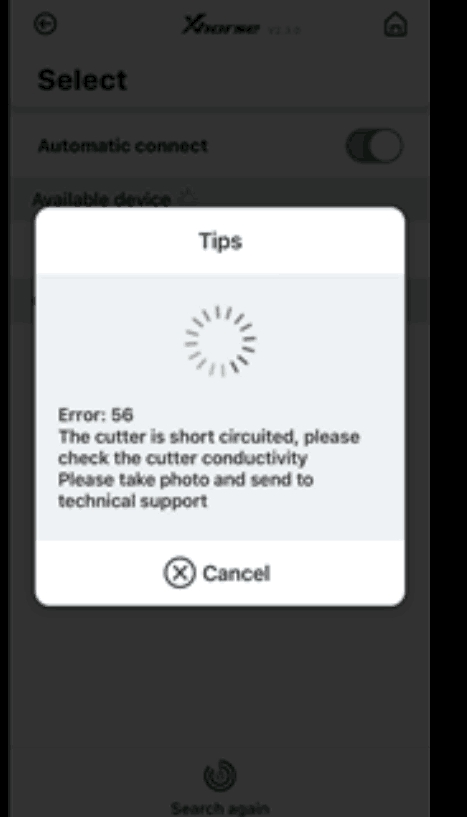

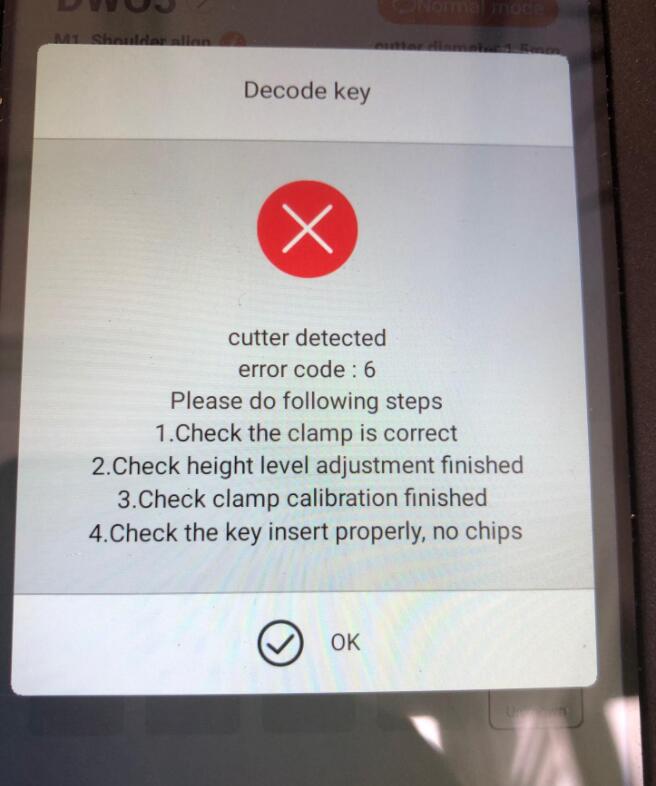

3)"Error: 56" "error code: 6"

Solution:

Check the steps as the prompts. (height level adjustment, clamp calibration etc.)

Do the Electrical Conductivity Measurement.

If the cutter and the probe don't conduct, disassemble the machine and test abnormal conductivity of the cutter/probe.

4)"error code: 17 No key is detected, please check whether a key is correctly positioned and selected"

Solution: Put shim below to raise the original key so the machine could learn it

5)Cutter wont touch key blade

Reason

The problem is a dysfunctional battery.

The machine disconnects and the probe & the cutter restore because it is powered down and reboot automatically.

Solution

Buy a new battery and replace the broken one.

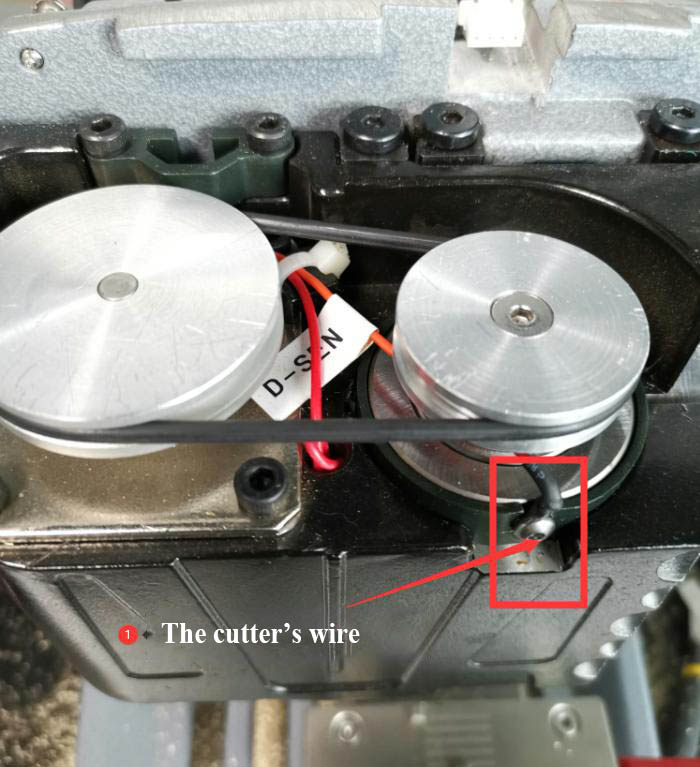

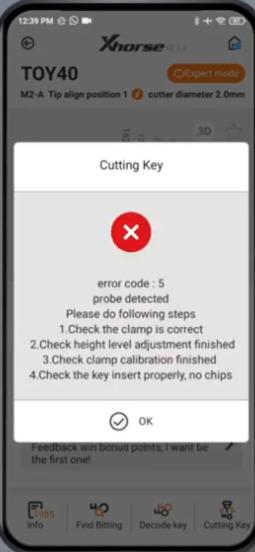

6)"error code: 29"

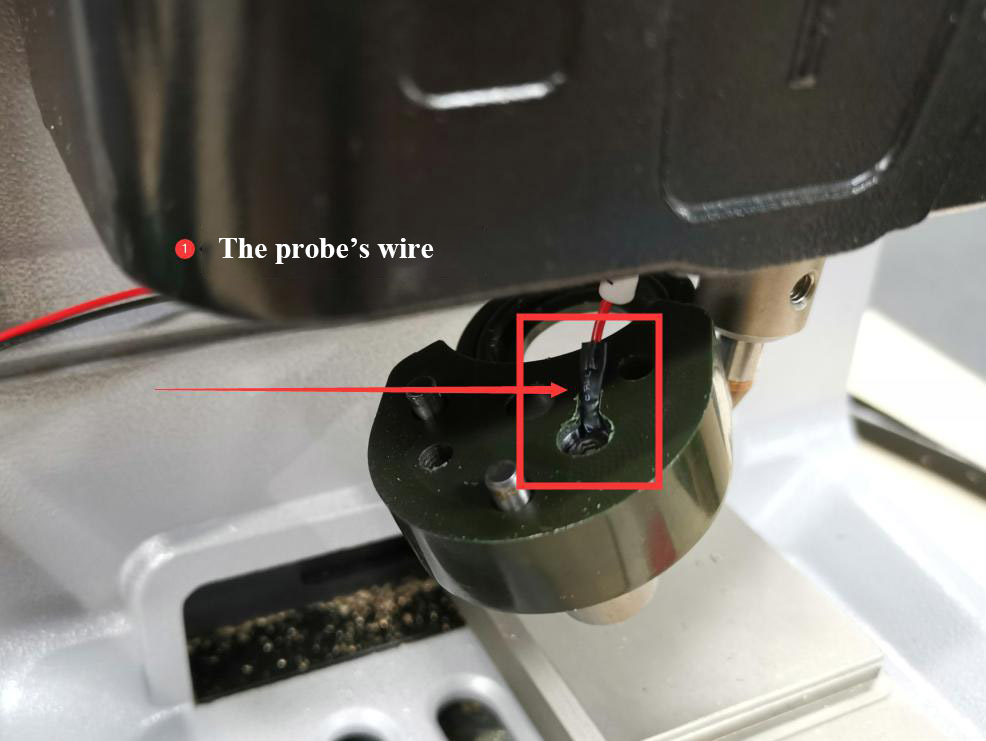

Reason: probe/ cutter is short-circuited due to metal filings

Solution:

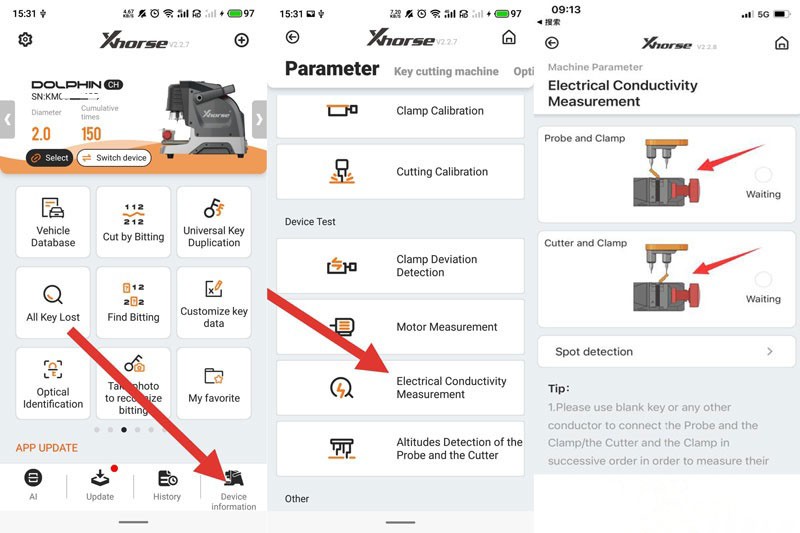

Test if probe/ cutter is short-circuited via Electrical Conductivity Measurement (cutter is short-circuited in this case)

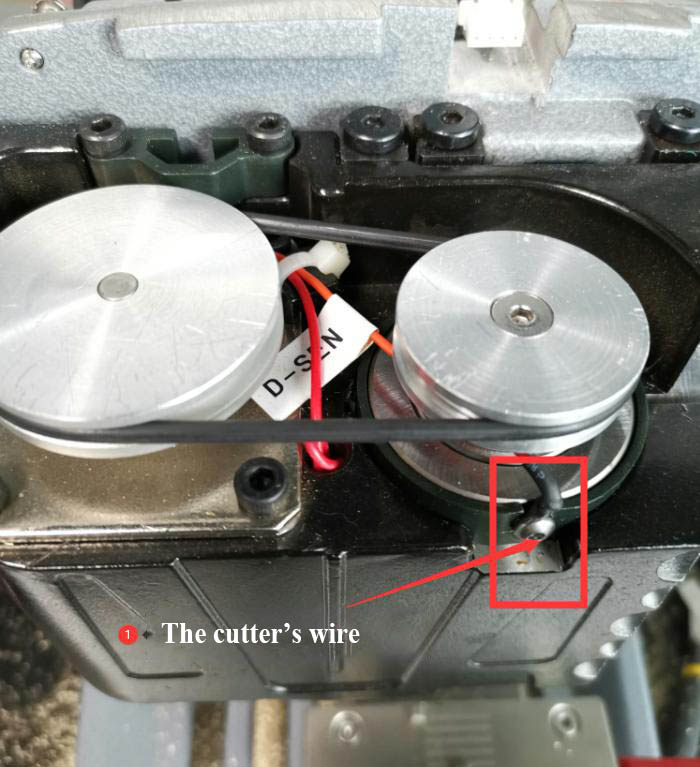

Open Machine and remove metal filings around the wire of cutter.

7)Noise and rough cutting

Solution:

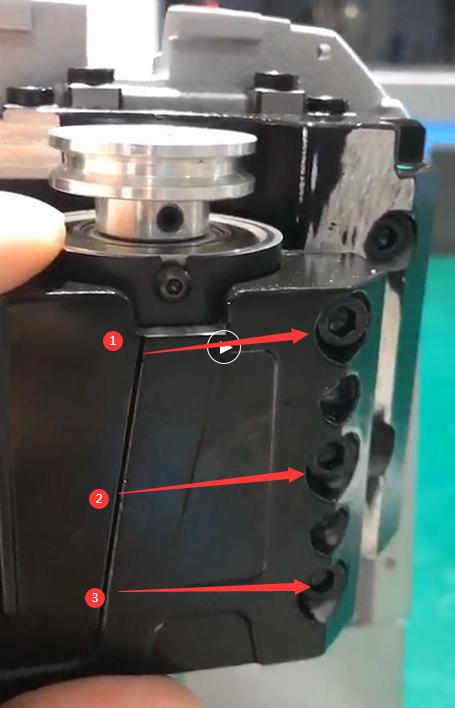

Step 1

Remove back cover of the machine.

Care the cables inside.

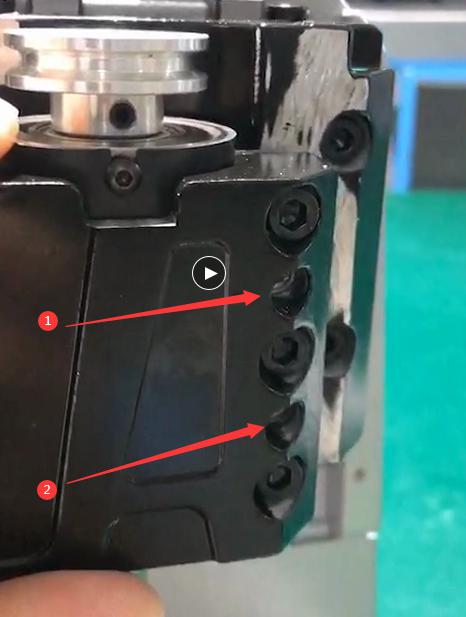

Step 2

Clean iron filings inside by a soft brush instead of a air gun.

Particularly clean filings on here.

Step 3

Lube ball screw and guide rail of the motor.

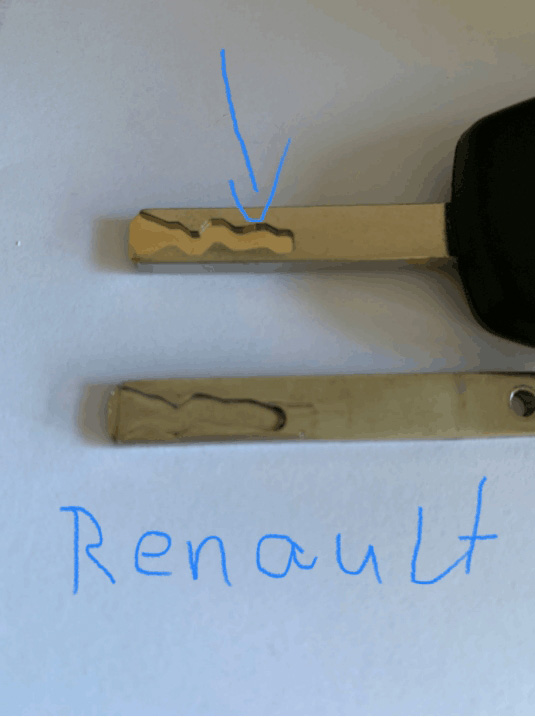

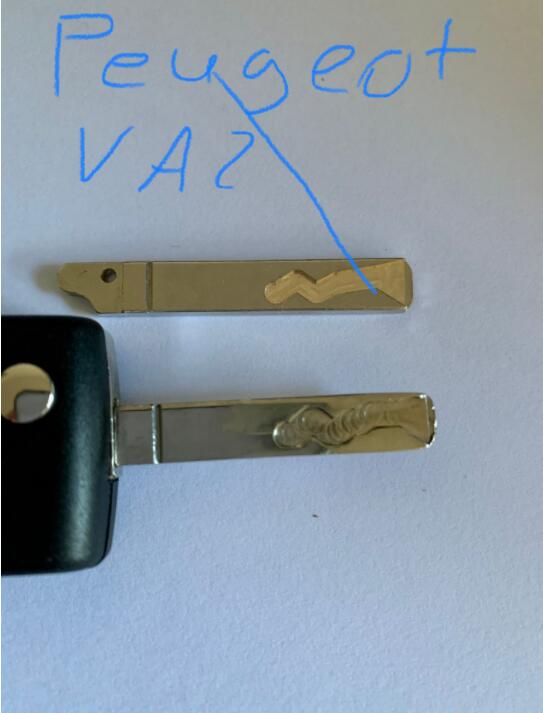

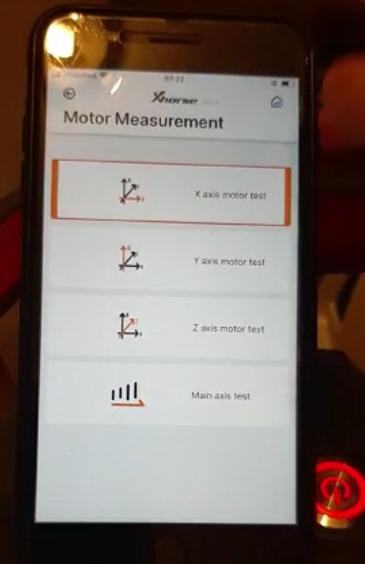

8)New keys of different types cut are incorrect

(in this case Renault, Peugeot VA2, HU100 Opel)

Possible reason:

The sensors or the cables inside don’t function well.

Solution:

Motor Measurement, machine is likely to be sent back to factory for repair (in this case X-axis is broken)

3.Guide

1)Xhorse APP Learn key via Photo

2)Electrical Conductivity Measurement

3)Test conductivity of cutter/probe

4)Work with Key Reader

5)Cut TOY40 Key by Code

6)Cut Used/Unfinished or Plastic/Aluminum Key

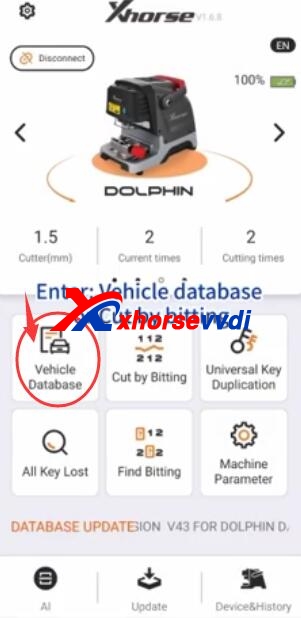

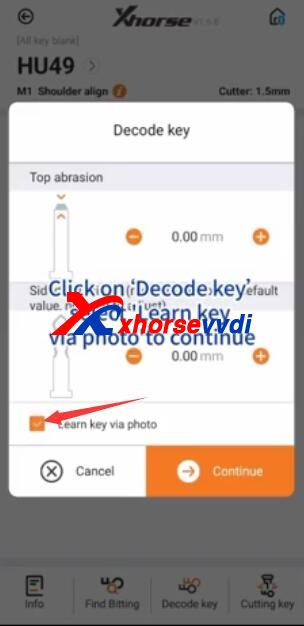

1)Xhorse APP Learn key via Photo

Xhorse APP Dolphin XP-005 can support read key bitting from key blade photo.

1.Choose vehicle database in xhorse app, Dolphin xp-005.

2.Choose the car brand.

3.Jetta,then HU49.

4.Tick on “Learn key via Photo”

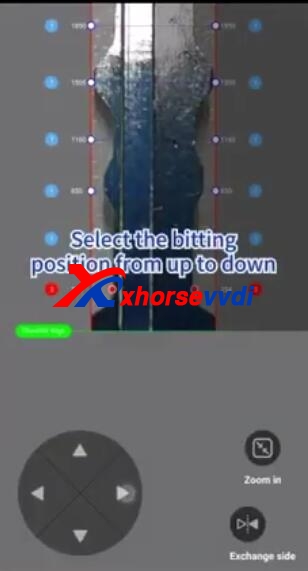

5.Please put the key blade horizonal in the fixed area,keep key on the top.

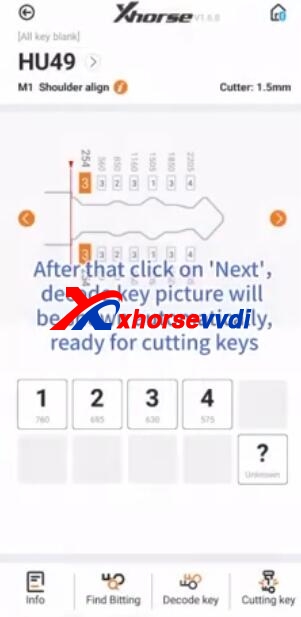

6.Rotate and zoom in the photo,adjust photo to the align line.

7.Dcode OK,then continue to cut key.

2)Electrical Conductivity Measurement

Go to Xhorse app.

Device information>>Electrical Conductivity Measurement

1)Probe and clamp

2)Cutter and clamp

Use a blank key or a conductor to short-circuit the clamp and the probe/cutter as the prompt.

3)Test conductivity of cutter/probe

Step 1

Unscrew the back of Dolphin XP-005, and watch the cables inside.

Step 2

Remove the back.

Unscrew the cable and the two Phillips screws.

Turn to the front side.

Unscrew the little rubber cover, and at behind are screws.

Then unscrew the long metal by a hexagon bar wrench.

Step 3

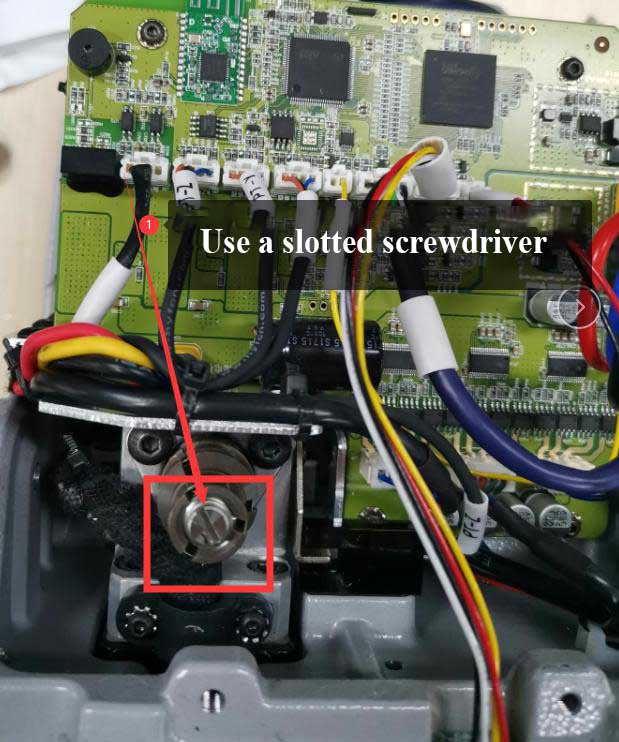

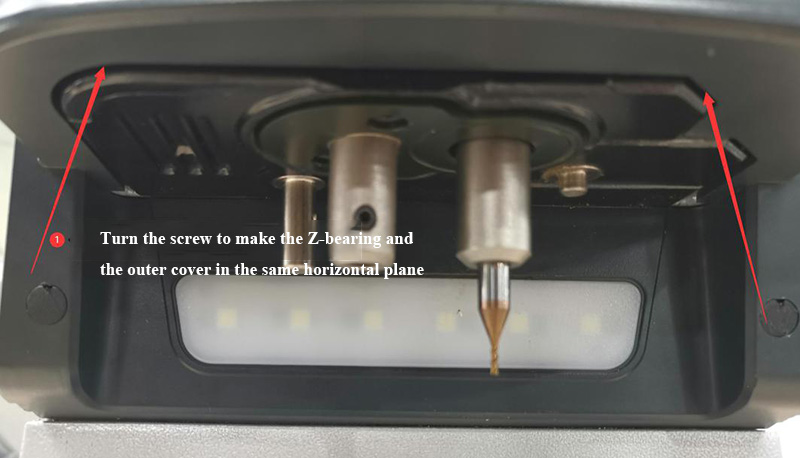

Use a slotted screwdriver to turn the screw so that the Z-axis and the outer cover are in the same horizontal plane.

Take down the outer cover of the Z-axis after the adjustment.

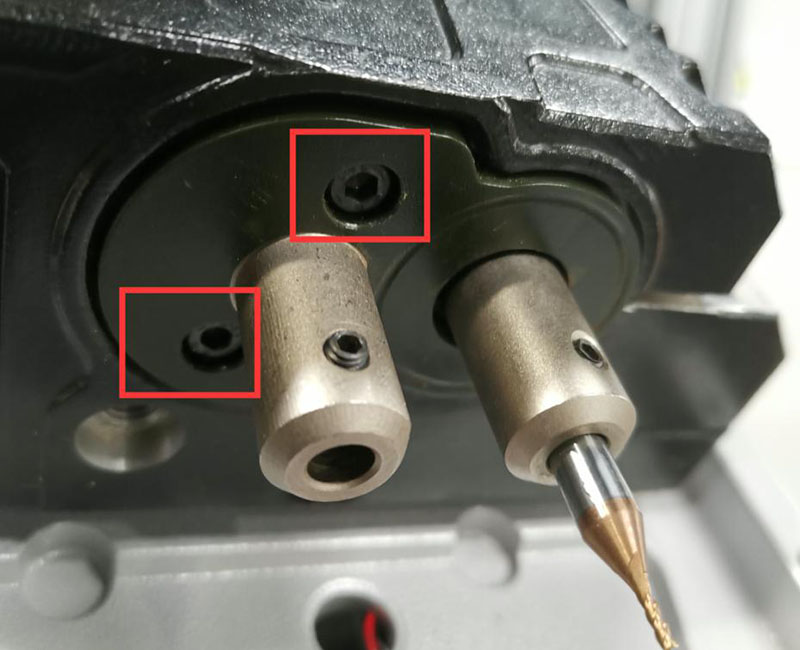

Unscrew the screws beside the probe.

Care the wire inside when removing the base.

Step 4

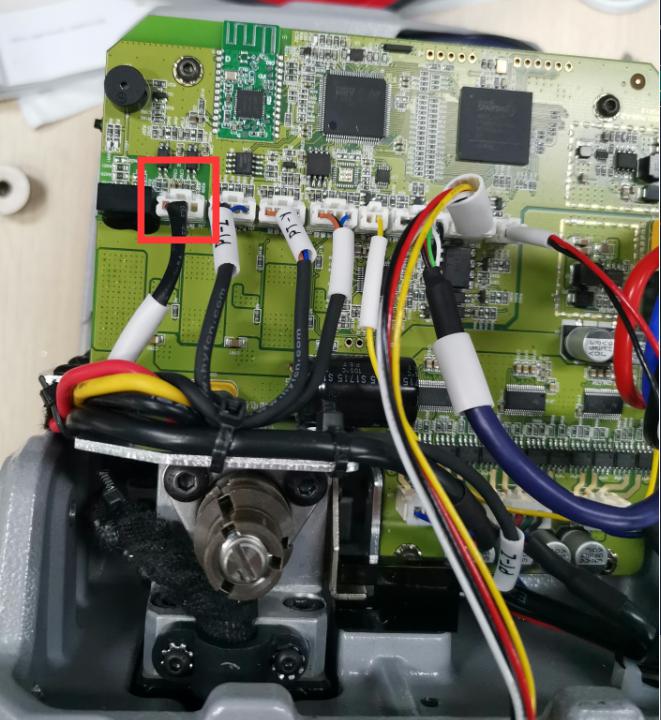

When the above steps are complete, now we can test whether the cutter’s wire and the probe’s wire are circuited or short-circuited.

The wires should be tested together with wires in the power board.

Unplug and plug the wire in the power board again before we test if the conductivity is normal.

Step 5

This step is to test the cutter’s conductivity.

Unscrew the three screws on the Z-axis,

and fasten the two screws until we get a gap to take down the Z-axis.

Press the cutter’s hole and push the axis up.

Check if the white paper is broken.

If so, replace it.

If not, check if there are some iron filings inside the axis hole.

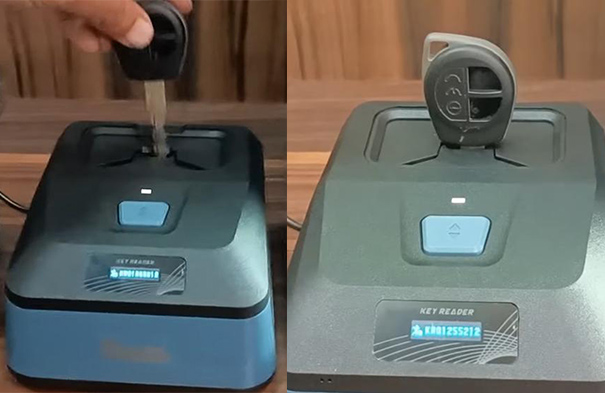

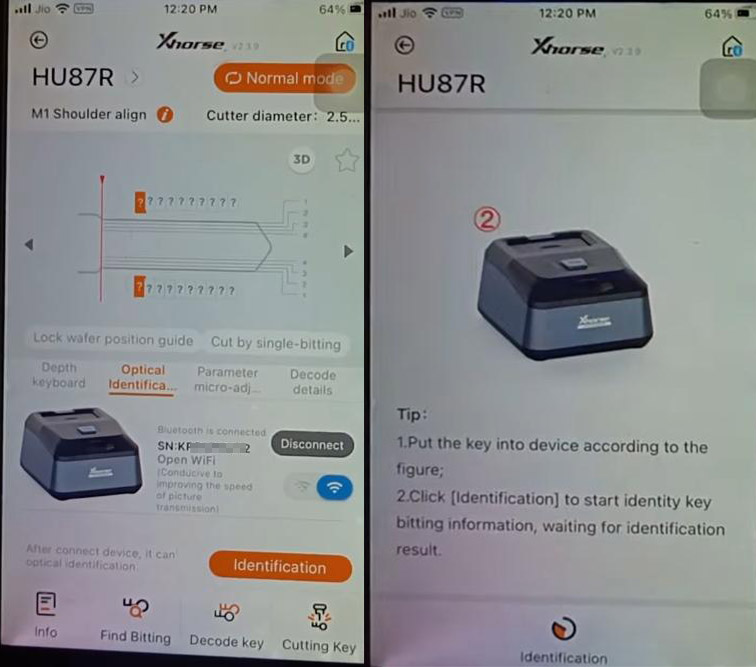

4)Work with Key Reader

Step 1. Decode

Path (Xhorse app):

Vehicle database>>Suzuki>>Swift>>new(after 2019)>>HU87R>>Optical identification>>Identification

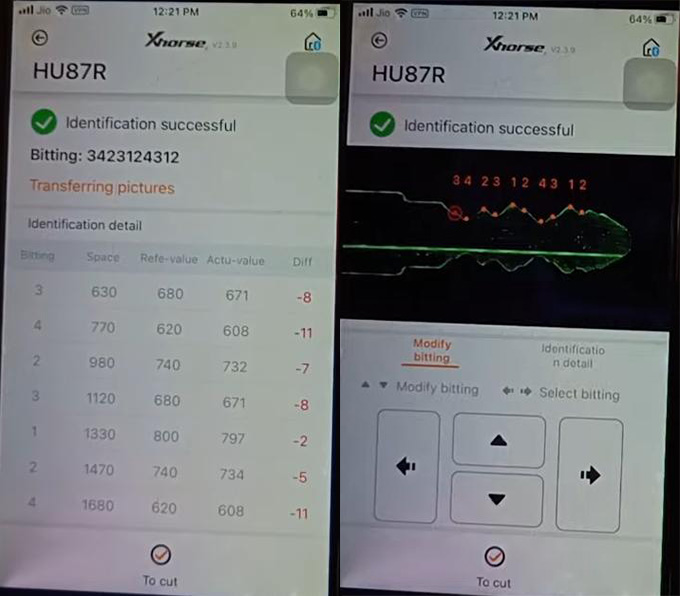

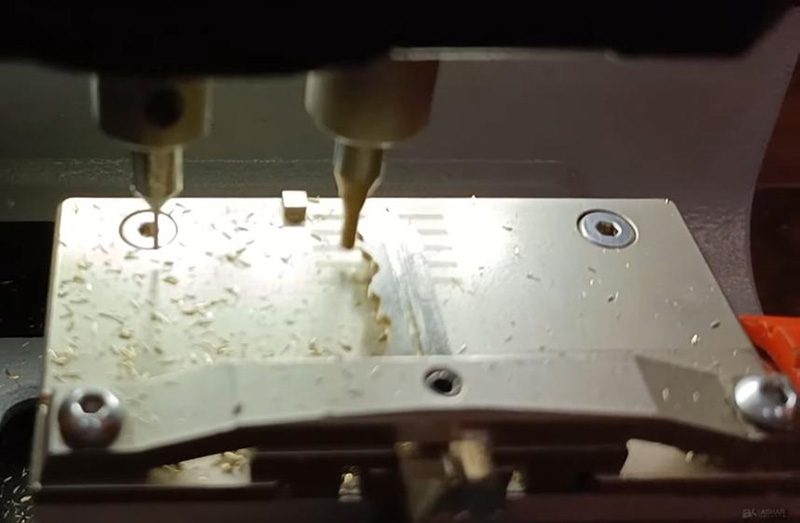

Step 2. Cut

Put a new key blank on clamp M1 as required and click on “Cutting Key”.

Comparison

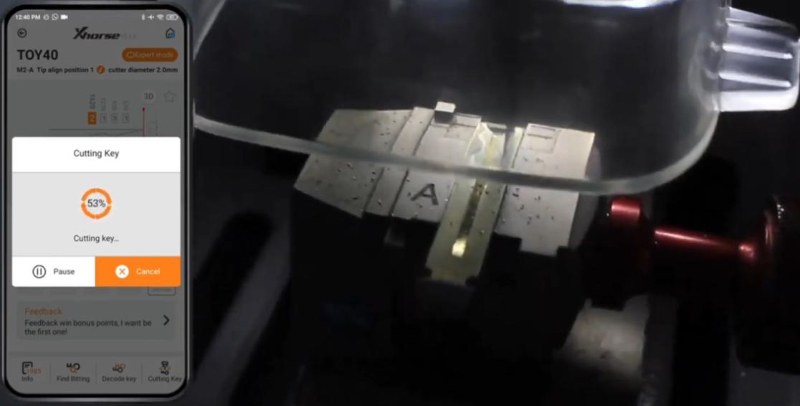

5)Cut TOY40 Key by Code

On Xhorse app, go to

All Key Lost>>Toyota

Input key code “88999”.

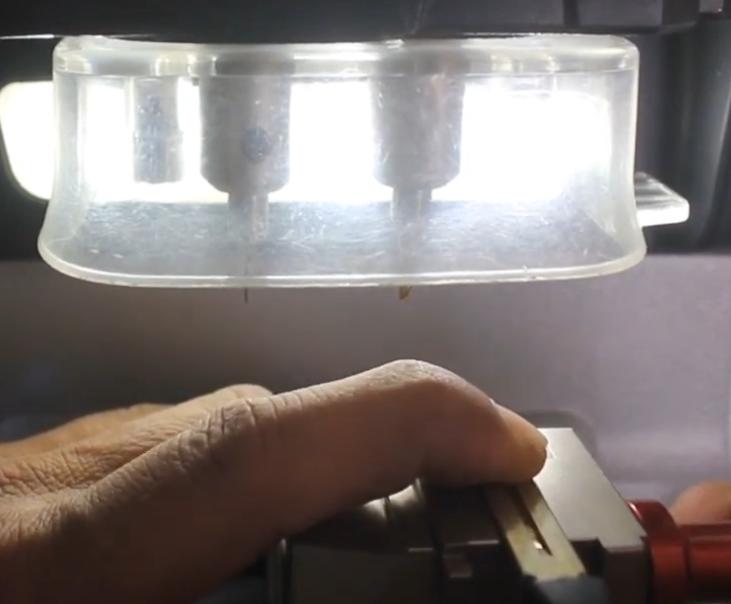

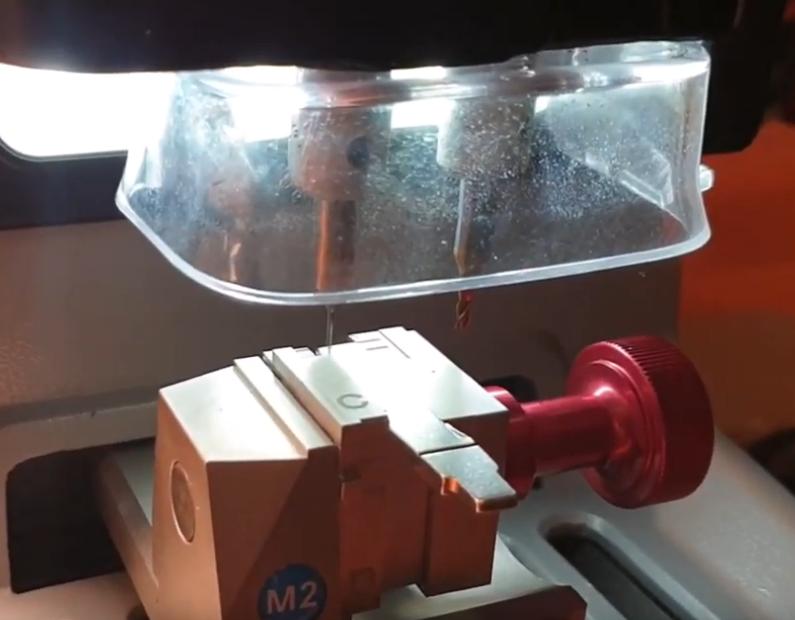

Prepare paper shims. (XP005 probe can’t detect such keys with only one side, so we need raise key blank by shims)

Put shims in clamp first.

Then put key blank.

Click “Cutting Key”.

If app prompts “error code: 5”, then we have to make key blank higher.

Complete!

6)Cut Used/Unfinished or Plastic/Aluminum Key

Step 1

Put a new blank of the same type for the probe to detect.

Step 2

Once the identification is complete, click “Pause”.

Step 3

Remove the new blank, put the semi-cut key back in, and click “Continue”.

Step 4

Repeat process for the other side if needed.